inSMTDuring solder paste surface mount processing, short circuits may occur, mainly in fine-pitch areasICBetween the pins, it is thus also called "bridging". The occurrence of short-circuit phenomena will directly affect the performance of the product and lead to the production of defective products. ForSMTThe phenomenon of short circuit in surface mount technology (SMT) requires great attention. Now, let's take a look at Shenzhen JJYSolder paste manufacturerLet me explain:

I. Template

SMTThe bridging phenomenon that occurs in surface mount technology (SMT) processing is mostly due toICThe pin spacing is relatively small, which usually occurs when the pin spacing is0.5mmOr in smaller cases; Therefore, if the template design is improper or there is a slight oversight in the printing, a short circuit is very likely to occur.

Solution: For a spacing of0.5mmAnd belowICBecause of itPITCHIt is small and prone to bridging. Keep the length direction of the steel mesh opening unchanged, and the opening width is0.5~0.75Pad width. The thickness is0.12mm~0.15mmIt is best to use laser cutting and polishing treatment to ensure that the opening shape is an inverted trapezoid and the inner wall is smooth, which is conducive to the effective release of solder paste and good forming during printing, and can also reduce the frequency of cleaning the screen plate.

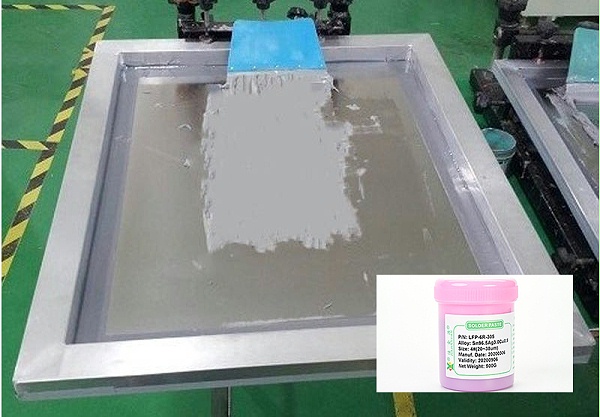

Ii. Pre-press printing

SMTIn surface mount technology (SMT) processing, printing is also a very important step. To avoid short circuits caused by improper printing, the following issues should be noted:

1Types of scrapers: There are two types of scrapers, plastic scrapers and steel scrapers. ForPITCH≤0.5mmtheICWhen printing, a steel squeegee should be selected to facilitate the formation of solder paste after printing.

2Adjustment of the scraper: The operating Angle of the scraper is as follows45°Printing in this direction can significantly improve the imbalance in the opening directions of different solder paste templates, and at the same time, it can also reduce the damage to the openings of fine-pitch templates;The pressure of the scraper is generally30N/mm².

3Printing speed: The solder paste will roll forward on the template under the push of the squeegee. Fast printing speed is beneficial for the rebound of the template, but at the same time it will hinder the missed printing of solder paste;However, if the speed is too slow, the solder paste will not roll and finish on the template, resulting in poor resolution of the solder paste printed on the pad. Generally, for fine-pitch printing, the speed range is10mm/s~20mm/s.

Iii. Solder paste

The correct choice of solder paste is also of great significance for solving the bridging problem.0.5mmAnd below the spacingICWhen using solder paste, the particle size should be selected20~45umThe viscosity is800~1200pa.sLeft and right. The activity of solder paste can be determined based onPCBIt is determined by the degree of surface cleanliness, which is generally adoptedRMAGrade.

Iv. Mounting Height

ForPITCH≤0.5mmtheICIt should be adopted during the mounting process0Distance or0-0.1~-0.1mmThe mounting height should be adjusted to prevent the solder paste from forming and collapsing due to an excessively low mounting height, which could cause a short circuit during backflow.

V. Reflux

inSMTDuring the reflow process of surface mount technology (SMT) processing, if the following situations occur, it may also lead to a short circuit phenomenon, such as:

1The heating rate is too fast;

2Excessively high heating temperature;

3The solder paste heats up faster than the circuit board;

4The wetting speed of the flux is too fast, etc.

As a 16-year-old veteran solder paste manufacturer, JJY has been dedicated to the research and development as well as production of solder paste for many years. The solder paste we produce is of stable quality, without solder connection, false soldering or monument erection. No residue, Wuxi beads, bright and full solder joints, firm solder joints, and excellent electrical conductivity. If you have any needs, please feel free to contact us.