inSMTDuring the surface mount technology (SMT) processing, if the process control measures are not implemented properly, it is very easy for some minor quality problems to occur. For instance, the occurrence of poor processing phenomena such as material spatter and flux splashing is not only due to the spatter of materials, but also the spatter of solder and flux. This is caused by the boiling of flux or contamination of solder paste during reflow soldering. These spatter can fly from the solder joint to several millimeters or even tens of millimeters away from it. This phenomenon poses a hidden danger to the safety control of production and processing. ForsmtIn terms of the quality of the patch, it is a phenomenon that should be avoided as much as possible. Below, JJY solder Paste Manufacturer will share with you how to prevent splashing:

I. Causes

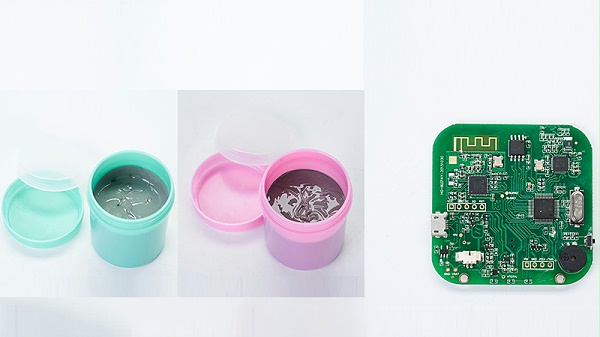

1,SMTMost of the splashing substances such as material throwing produced during processing are caused by the moisture absorption of solder paste. Due to the presence of a large number of hydrogen bonds, water molecules accumulate considerable heat energy before it eventually breaks and evaporates. Excessive heat energy combines with water molecules and directly triggers vaporization activities,That is, splashes are produced. Solder paste exposed to a humid environment or solder paste with hygroscopic additives will intensify the absorption of moisture. For example, water solubility(Also known as the washed type)Once the solder paste is exposed90%RHThe conditions have been granted.20minA relatively large amount of splashes will be produced.

2,SMTDuring the solder paste reflow process in surface mount technology (SMT) processing, the evaporation of solvents, the evaporation of water vapor produced by reduction, and the condensation process of solder cause the displacement of flux droplets. It is both a normal physical process of solder paste reflow soldering and a common cause of flux and solder spatter. Among them. Solder condensation is a major reason. During refluxes, the interior of the solder powder melts. Once the surface oxides of the solder powder are eliminated through the reaction of the flux, countless tiny solder droplets will fuse and form an integrated solder. The faster the reaction rate of the flux is, the stronger the coagulation driving force will be. Therefore, it can be predicted that more severe splashing will occur.

3The influence of the reaction rate or wetting rate of flux on flux spatter has been studied. Wetting time is the most important factor determining flux spatter. A slower wetting rate is less likely to cause spatter.

4If the steel mesh is not wiped clean, it may also cause the bottom of the template to be contaminated by solder paste, which eventually remains on the surface of the circuit board, resulting in a phenomenon similar to tin splashing.

Ii. Suggestions for Improvement

Generally speaking, the ways to reduce splashes are:

In terms of technology

1Avoid solder paste printing in a damp environment.

2Use a long preheating time or a high preheating temperature curve.

3Reflow welding is carried out using an air atmosphere.

In terms of materials

1Use solder paste with low hygroscopicity.

2Use solder paste with a slow wetting rate.

The above content about how to prevent splashing is explained by Shenzhen JJY Solder Paste Manufacturer. If you want to know more about solder paste products, please follow and interact with us.