With the advancement of technology, modern electronic devices such as smart phones and tablet computers are increasingly pursuing thinness, lightness and portability. This trend promptsSMTThe size of electronic components in (surface mount technology) processing is constantly shrinking, from the past0402Resistors and capacitors have gradually transformed into smaller ones0201Size. However, as the size of components decreases, how to ensure the quality of solder joints has become an important issue in high-precision surface mount technology (SMT) processing. After all, solder joints serve as a connection between electronic components andPCBThe quality and stability of the bridge of the board are directly related to the overall quality of the electronic equipment,The following is JJYSolder paste manufacturerLet me explain it to everyone.

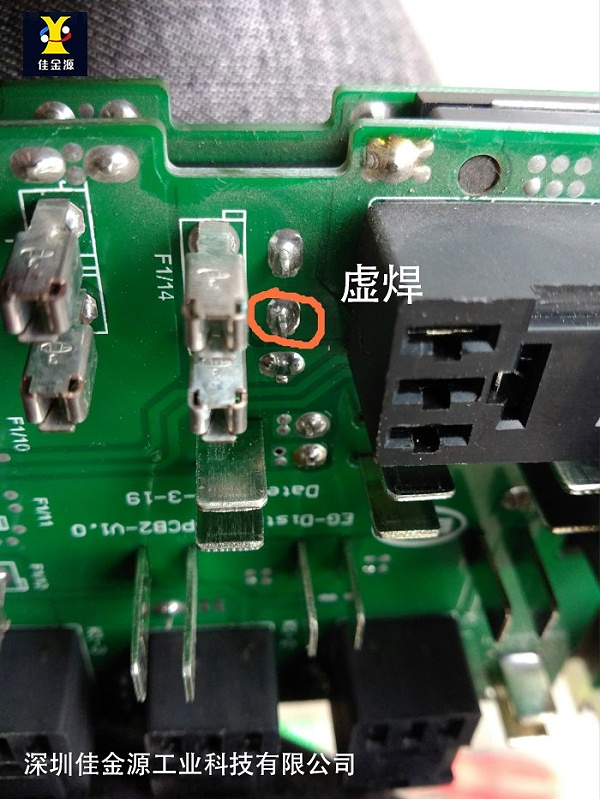

1.SMTJudgment of false soldering in surface mount technology (SMT) processing

inSMTDuring the surface mount technology (SMT) processing, false soldering is a problem that cannot be ignored. To detect and handle the phenomenon of false soldering in a timely manner, we can adopt the following methods for detection:

1Use professional equipment such as online testers for inspection to ensure that the quality of the weld points meets the standards.

2For visual inspection or useAOIThe (automatic optical inspection) equipment conducts an inspection. If it is found that the welding material of the solder joint is insufficient, the solder wetting is poor, there are broken seams in the middle of the solder joint, the surface layer of the solder is convex spherical or withSMDSituations such as non-compatibility need to be taken seriously. Even minor problems can lead to a decline in equipment performance or malfunction. At this point, we need to further determine whether there is a problem of batch false soldering.

Ii. Causes and Solutions of False Soldering

ForSMTThe problem of false soldering that occurs in surface mount technology (SMT) processing requires an in-depth analysis of its causes and the adoption of corresponding solutions:

1Pad design flaws: Unreasonable pad design, such as the presence of through holes, can easily lead to solder loss and insufficient soldering materials. To solve this problem, we should try to avoid using pad designs with through holes and ensure that parameters such as pad spacing and area comply with the specifications.

2,PCBPlate oxidation or contaminationPCBThe oxide layer or contaminants on the surface of the board can affect the wettability and adhesion of the solder, thereby leading to false soldering. To solve this problem, we can use an eraser to remove the oxide layer or use cleaning agents such as anhydrous ethanol to clean itPCBContaminants on the surface of the board.

3Solder paste being scratched: InSMTDuring the surface mount technology (SMT) processing, the solder paste may be scratched or scraped off, resulting in a reduction in the amount of solder paste on the solder pads. To solve this problem, we can replenish the solder paste in time to ensure that there is sufficient soldering material at the solder joints. When replenishing solder paste, tools such as dispensing machines or bamboo sticks can be used for the operation.

In conclusion,SMTThe problem of false soldering in surface mount technology (SMT) processing is one that requires sufficient attention. By adopting professional testing equipment and scientific solutions, we can promptly detect and handle the phenomenon of false soldering, ensuring the overall quality and stability of electronic devices.

As a 16-year-old veteran solder paste manufacturer, JJY has been committed to the research and development, production and sales of solder paste. Our product quality is stable, with no solder connection, no false soldering, and no monument erection. Residual Wuxi beads, bright and full solder joints, firm welding, and excellent electrical conductivity. If you have any needs, please feel free to contact us.