SMTAs a key technology in modern electronic manufacturing, surface mount technology (SMT) processing may encounter various challenges in the practical process. This article will explore these issues and provide effective solutions to help readers deal with them more effectivelySMTDifficulties in surface mount technology (SMT) processing,Now, by Shenzhen JJYSolder paste manufacturerLet me explain:

Question 1: Patch offset

inSMTIn surface mount technology (SMT) processing, SMT offset is a common problem. Due to factors such as temperature and vibration, the patch is soldered toPCBDisplacement may occur at this time, resulting in a decrease in welding accuracy.

Solution:

1Use precise positioning tools to ensure that the patch is accurately placedPCBUp.

2Control the temperature and time during the soldering process to reduce the risk of patch offset.

3Use adhesive or glue to fix the patch to prevent it from shifting during the soldering process.

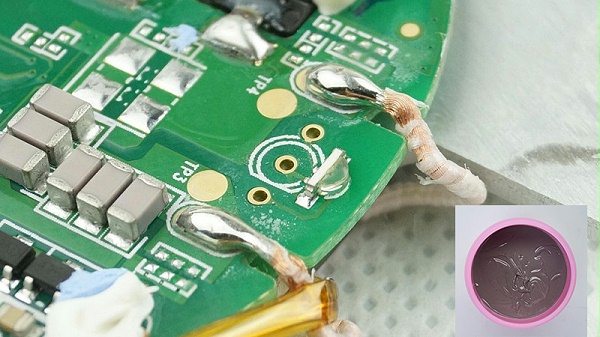

Question 2: Poor welding quality

So is the poor welding qualitySMTOne major challenge in surface mount technology (SMT) processing Poor welding may lead to circuit faults.

Solution:

1Ensure that the welding equipment is properly maintained, such as keeping the welding joints clean and ensuring an appropriate heating temperature.

2Select appropriate welding materials and techniques, such as choosing suitable solder wires and welding head shapes.

3Before welding, conduct detailed inspections and tests to ensure the reliability and stability of the welding points.

Question 3: Electronic components are damaged

inSMTDuring the surface mount technology (SMT) processing, damage to electronic components may be caused by improper operation or external factors.

Solution:

1During the operation process, take anti-static measures, such as wearing anti-static gloves and using anti-static tools.

2Pay attention to controlling the temperature and humidity during the storage and handling of electronic components to avoid adverse effects on them.

3Choose suppliers with good reputation and quality assurance to ensure the acquisition of high-quality electronic components.

JJY Solder Paste Factory produces a wide range of solder paste products, including lead-free solder paste, halogen-free solder paste, silver-containing lead solder paste, syringe solder paste, nickel-plated environmentally friendly solder wire, solder bar, etc. We can provide technical support. If you have any needs or technical questions regarding soldering, please feel free to leave a message online to interact with us!