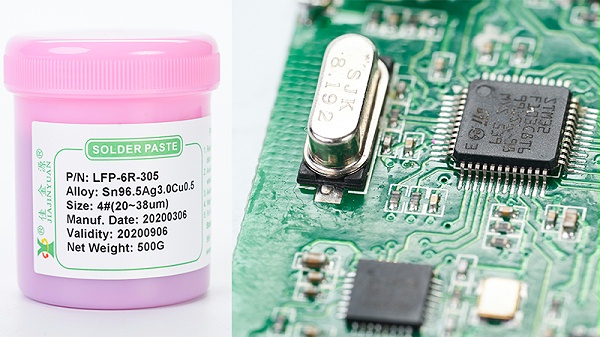

SMTThere are many factors that affect the processing quality in surface mount technology (SMT) processing, and the quality of solder paste printing is one of them. NowadaysSMTIn the processing plant, solder paste printing is mainly accomplished by using fully automatic solder paste printers. Below, Shenzhen JJY Solder Paste Manufacturer will briefly introduce some common key points of solder paste printing to you:

I. Scraper Angle

The smaller the Angle of the scraper, the greater the downward force applied to the solder paste, and at the same time, it will be more difficult to scrape off the solder paste on the surface of the steel mesh. If the Angle is too large, the solder paste filling effect will also be relatively poor.

Recommended scraper Angle45°~75°Generally, fully automatic machines are fixed at60°Left and right.

Ii. Scraper speed

SMTThe influence of the scraper speed on the solder paste pattern in the solder paste printing of surface mount technology (SMT) processing is complex. Generally speaking, the speed is100mm/sPreviously, the filling time played a dominant role; in100mm/sAfter that, the viscosity of the solder paste plays a dominant role. But one thing is common, that is, the speed is too fast (higher than)180mm/sOr too slow (lower than.20mm/sNone of them is conducive to the filling of solder paste.

Recommended range of scraper speed:

1Board for installing components with ordinary spacing:140~160mm/s;

2Board for installing components with fine pitch:25~60mm/s.

Iii. Scraper Pressure

So is the pressure of the scraperSMTAn important parameter in the solder paste printing process of processing is that it can meet the requirements of the bottom surface of the steel mesh andPCBUnder the premise of gapless contact and surface solder paste scraping clean, that is, when the solder paste can be fully filled and scraped clean, the smaller the pressure of the squeegee, the better. Excessive pressure may cause the middle of the large-sized pad pattern to be dug out. The pressure of the scraper is generally in accordance with0.5kg/1Make the initial Settings and then adjust according to the graphics.

Iv. Disconnection Speed

Generally speaking, if the de-meshing speed is fast, it is easy for solder paste to remain on the hole wall, resulting in insufficient solder or sharp edges. If the disconnection speed is too fast, it may also cause the steel net to rebound, resulting in the "dog's ear" phenomenon.

Let the advanced solder paste technology of JJY help you solve the problems of solder paste printing! If you have any other questions, please feel free to consult us to learn more about professional solutions for solder paste!