inSMTIn surface mount technology (SMT) processing, the quality requirements for solder joints are extremely strict. inSMTDuring processing, we need to make judgments from three aspects:Good electrical contact, sufficient mechanical strength and neat appearance. Similarly, we can also analyze the causes of adverse phenomena from five aspects: operators, equipment, materials, processes and the environment.

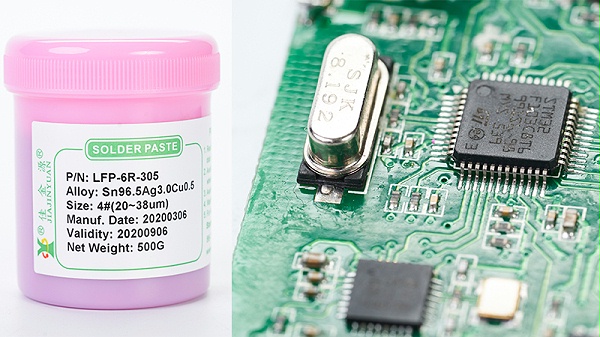

Reflow soldering isSMTThe step close to the end in the production process of surface mount technology (SMT) processing and responsible for the soldering of components. The defects in reflow soldering are a combination of those in printing and surface mount technology,The package includes insufficient solder, short circuit, side stand, misalignment, missing parts, multiple parts, wrong parts, reverse side, reverse side, upright tablet, crack, solder bead, false soldering, voids, gloss,Among them, stele standing, cracks, tin beads, false soldering, voids and gloss are the specific defects after soldering. The following is JJYSolder paste manufacturerLet me give you a brief introductionSMTWhat are the common soldering defects in surface mount technology (SMT) processing?

1Erect a monument:The phenomenon where one end of a component leaves the pad and stands upward at an Angle or upright.

2Tin connection or short circuit:Solder connection occurs between two or more solder joints that should not be connected,Or there is a poor connection between the solder at the solder joint and the adjacent wire.

3Displacement and misalignment:The component is laterally within the plane of the pad(Level)Vertical(Vertical)Or the rotation direction deviates from the predetermined position.

4Empty welding:There is no assembly phenomenon where the solderable end of the component is connected to the pad.

5Reverse:The polar components were mounted in the wrong direction.

6Wrong item:The model and specification of the components mounted at the specified positions do not conform to the requirements.

7"Few pieces":It is required that no materials be mounted at the positions where components are present.

8Exposed copper:PCBAThe green oil on the surface has fallen off or been damaged,This results in the copper foil being exposed.

9"Bubbling":PCBA/PCBThe surface undergoes regional expansion deformation

10Tin hole:After passing through the furnace,There are blowing holes and pinholes on the solder joints of the components.

11Tin cracking:The tin surface is cracked.

12Block the hole:Solder paste remains in the plug-in hole/Screw holes and the like cause the hole diameter to be blocked.

13Cross one's feet:The pins of multi-pin components are warped and deformed.

14Stand sideways:SMTIn surface mount technology (SMT) processing, the side of the component soldering end is directly soldered.

15False welding/False welding:The components are not welded firmly,Poor contact may occur under external force or internal stress,Sometimes disconnected, sometimes connected

16The reverse side/"反白" 可 以 翻 译 为 "reverse white":The surface of the component is silk-screened and adheredPCBThe other side of the board,The product name and specification of the silk-screened font cannot be recognized.

17Cold welding/Non-melting tin:The surface of the solder joint is not shiny,The crystals were not completely melted to achieve a reliable welding effect.

18Less tin:The solder content of the component pads is insufficient.

19Multiple items:PCBIt is not required that components be attached to the positions where there are components.

20Tin tip:The tin dots are not smooth,There are sharp peaks or burrs

21Tin beads:PCBAThere are spherical tin spots or tin substances on it.

22"断路" 可 以 翻 译 为 "Open road":Component orPCBAThe line is disconnected in the middle.

23The component rises:The component body floated and detached after weldingPCBThe surface phenomenon.

Shenzhen JJY Industrial Technology Co., Ltd. mainly engages in the production and operation of:SMTSolder paste manufacturers of solder paste, syringe solder paste, lead-free solder wire, wave soldering bar, automatic soldering wire, etc.