inSMTDuring the surface mount technology (SMT) process, the phenomenon where components stand upright after reflow soldering (usually resistors and capacitors) is called "standing upright" or "Jia Jinyuan"Solder paste manufacturerLet me share with you the reasons for the erection of a monument and the corresponding solutions:

I. Analysis of the Causes of Monument Erection

1The force distribution at both ends of the components is uneven, and the tin content is inconsistent.

2The preheating temperature is unreasonable and the preheating temperature rise rate is too fast.

3Machine mounting offset, poor mounting accuracy, and severe component offset;

4The thickness of the solder paste printing is uneven, the printing accuracy is poor, and the misalignment is severe.

5Improper setting of furnace temperature, either too high or too low;

6The nozzle is severely worn and the position is misaligned during mounting.

7Oxidation of the soldering coating at both ends of the component pins causes the solder paste to have different wetting forces. When two different wetting forces are generated, wetting deviation or stmonument formation will occur.

Ii. Corresponding Handling measures

1When opening the steel mesh, make the two ends of the welding pad equal.

2Adjust the preheating and heating rate to makepcbThe plates meet the corresponding temperature requirements in each temperature zone.

3Adjust the machine mounting offset, debug in time to avoid hardware problems;

4Adjust the position of the printing press;

5Adjust the temperature of the reflow oven

6ReplaceOKSuction nozzle

7When conditions permit, replace the oxidized material at the pins in a timely manner to reduce defects. If the materials are not replaced, the defects should be reduced in time by optimizing the furnace temperature curve or replacing the solder paste with strong soldering ability.

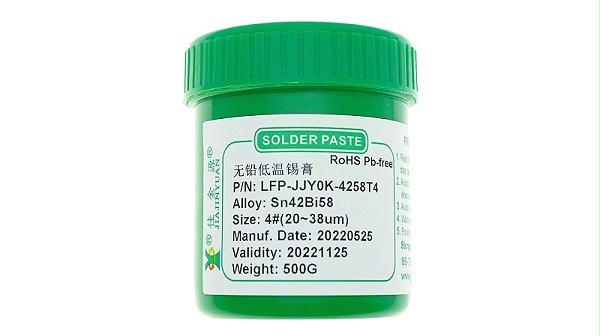

As a 15-year-old veteran solder paste manufacturer, JJY has been dedicated to the research and development and production of solder paste for many years. The quality of the solder paste is stable, without solder bonding, false soldering or establishing a reputation. No residue, Wuxi beads, bright and full solder joints; The weld points are firm and have excellent electrical conductivity. If you have any needs, please feel free to contact us.