ForSMTFor surface mount technology (SMT) processing and soldering, many customers usually have requirements for the brightness of the solder joints. After all, the brightness of the solder joints can give us a refreshing feeling. However, during the soldering process of surface mount technology (SMT) processing, it cannot be guaranteed that the brightness of each solder joint will reach a shiny level. Well,SMTWhat are the reasons for the insufficient gloss of solder joints in surface mount technology (SMT) processing? The following is JJYSolder paste manufacturerLet me explain:

1If the tin powder in the solder paste undergoes oxidation, it will affect the gloss of the solder joints.

2The glossiness is also related to whether additives that can produce a matting effect are added to the flux.

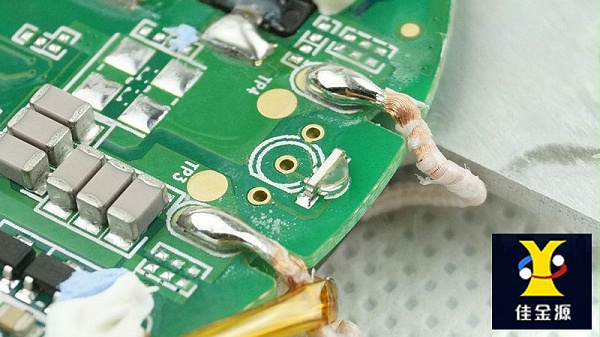

3InSMTIn the reflow soldering process of surface mount technology (SMT) processing, the preheating temperature is relatively low, resulting in residues that are difficult to evaporate remaining on the surface of the solder joints, which also affects the gloss of the solder joints.

4After welding is completed, if rosin or resin-like residues remain on the surface of the weld points, it will also affect the gloss of the weld points.

5Apart from the production and processing techniques, the selection of raw materials also has a significant impact on the glossiness of the solder joints. For instance, solder pastes containing silver and those without silver result in different glossiness of the solder joints. If there are requirements for the glossiness of the solder joints, it is necessary toSMTClear requirements should be put forward before the surface mount technology (SMT) processing is carried out, so as to facilitate the selection of production raw materials and processes.

JJY is a well-established solder paste manufacturer with a history of fifteen years, always dedicated to the research and development, production and sales of solder paste. The solder paste we produce is of stable quality, without solder connection, false soldering or monument erection. No residue, Wuxi beads, bright, full, firm solder joints with excellent electrical conductivity. If you have any needs, please feel free to contact us.