SMTProcessing refers to bonding components together through a solder paste soldering machinePCBThe abbreviation of the process on the circuit board. Whether the components can perform their functions normally and whether the circuit board can ultimately ensure normal operation and functional performance all depend on this. Therefore, process measurement control must be implemented for optimizationpcbaProcessing and assembly. This will ensure that costly errors will not be discovered in the future, which could lead to a high failure rate of the product and cause damagesmtThe reputation of the surface mount technology (SMT) processing factory

PCBThe process control of assembly mainly involves implementing some robust processes in the printing, installation and reflow soldering stages. Let's have an in-depth understanding of the assemblySMTSome details of welding defects. The success of solder paste printing determines whether the overall quality can meet expectations. Therefore, we need to have a detailed understanding and make an assessment of the quality abnormalities that can affect this process link.

inSMTBefore sampling, the following contents must be checked:

1.PCBThe contents to be detected

1,PCBWhether the smooth plate is deformed and whether the surface is smooth;

2Whether there is oxidation in the solder pads of the circuit board;

3Whether there is any exposure on the circuit board and copper clad laminate;

4,PCBWhether it has been baked for the prescribed time.

Ii. What should be checked before solder paste printing:

1The boards should not be stacked vertically and there should be no collisions between them.

2Whether the positioning holes are consistent with the holes opened in the template;

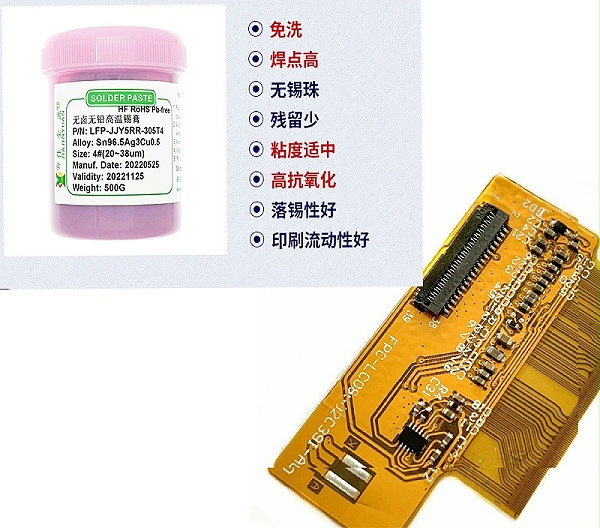

3Whether the solder paste has been thawed at room temperature in advance;

4Whether the selection of solder paste is correct and whether it has expired;

5,SPIWhether the solder paste detector has corrected the data;

6Whether the steel mesh and formwork have been cleaned and whether there is any flux residue on the surface;

7Whether there is warpage in the steel mesh;

8Whether the scraper parameters have been corrected and adjusted.

The above are the detailed checks to be carried out when officially entering the solder paste printing process. Although many of the tasks may seem trivial, they are very helpful for the quality of the product. At the same time, if you want to learn more about soldering, please continue to follow JJYSolder paste manufacturerLeave a message online to interact with us.