insmtIn the processLead-free solder pasteThe setting of the furnace temperature curve is a very important step, which directly affects the quality of the product. Therefore, we should determine the appropriate furnace temperature curve based on the process characteristics of lead-free solder paste. How exactly should it be done?Now, let's talk about how the general lead-free solder paste furnace temperature curve is set, as explained by Shenzhen JJY Solder Paste Manufacturer?

1Test the applicable temperature curve with relevant instruments:

Using a temperature curve measuring instrument is the best way to obtain and establish an applicable temperature curve. When measuring, fully assembled electricity must be used Road, Board: Carefully select several points on the circuit board. The selected points may be the most representative in terms of heat capacity, heat conduction and heat absorption(The largest or the smallest)The temperature sensor head is adhered to the selected measurement point with high-temperature tape or soldered with high-temperature solder. Then, the circuit board is sent into the reflow oven. The temperature curve is read by the computer through the interface provided by the measuring instrument. More advanced measuring instruments can be sent into the reflow oven along with the circuit board. The measuring instrument can store the temperature curve in the internal memory of the machine. It is read out by a computer or printer after the measurement is completed.

2The temperature curve should be analyzed in sections and briefly:

For any solder paste, there is no unique temperature curve. The information provided by the product is merely a guide to the working steps. The temperature curve of a solder paste must take into account factors such as the solder paste, fully assembled circuit boards, and equipment. A good temperature curve is not easy to obtain and requires repeated trials to achieve relatively satisfactory results.

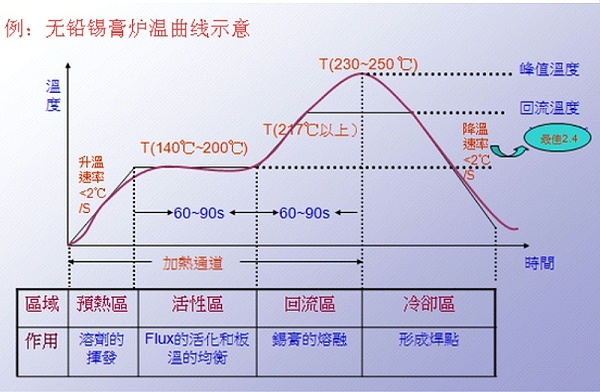

The furnace temperature curve is generally divided into four sections:aRapid heating section(That is, the preheating section),bInsulation sectioncWeld the reflux sectiondThe cooling section is followed by a brief analysis in the reverse direction from the cooling section.

3When setting the temperature of lead-free solder paste furnaces, the following points should be noted:

Temperature setting for lead-free solder paste furnaces,It is related to the type of solder paste and the temperature requirements of the heat-sensitive components to pass through the furnace.That is to say, the temperature curve should melt the solder paste,Meanwhile, the components must not be damaged.The set temperature value and the actual onePCBThere is a temperature difference on the board,Set value260,Perhaps the actual temperature of the solder pads on the board is only240Perhaps.,And be affected by the environment,Personnel,Materials,Machinery,Craft this5The influence in this aspect,Perhaps the set values for winter and summer are the same,But the temperature of the solder pads on the board is different.Therefore, the temperature-time curve measured in the furnace with a thermocouple should be taken as the standard.The standard of the curve is generally150℃-180℃have90-120seconds.220℃The above30-60seconds,230℃The above30Within seconds.

Only by mastering the method of setting the furnace temperature curve for lead-free solder paste can we ensure that the lead-free solder paste is in the best condition. The above methods are the suggestions given by JJY, a gold medal solder paste supplier, for everyone. You can use them as a reference. As a sixteen-year-old veteran solder paste manufacturer, we have always been committed to the research and development, production and sales of solder paste. Our solder paste is of stable quality, without solder disconnection, false soldering or monument erection. No residue, Wuxi beads, bright, full, firm solder joints with excellent electrical conductivity. If you have any needs, please feel free to contact us.