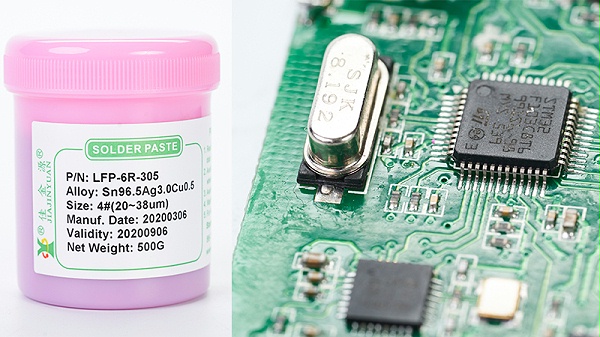

inSMTIn surface mount technology (SMT) processingSolder pastePrinting is a processing link that holds an important position, and inSMTThe processing is a relatively early production process and also a place prone to poor processing. Many poor problems in surface mount technology (SMT) processing are caused by errors in solder paste printing. Now, JJY Solder Paste Manufacturer will introduce to you the problems in solder paste printing:

1. Tip the tip

Cause: It might be caused by a gap in the scraper or excessive viscosity of the solder paste.

Avoidance or solution:smtFor surface mount technology (SMT) processing, appropriately reduce the gap of the squeegee or select solder paste with an appropriate viscosity.

Second, the solder paste is too thin

The causes are:1The template is too thin.2The pressure of the scraper is too high.3The solder paste has poor fluidity.

Avoidance or solution: Select templates of appropriate thickness; Select solder paste with appropriate particle size and viscosity; Reduce the pressure of the scraper.

Three. The thickness of the solder paste is inconsistent

Cause of occurrence:1The solder paste was not mixed evenly, resulting in inconsistent particle sizes.2The template is not parallel to the printed circuit board.

Avoidance or solution: Thoroughly mix the solder paste before printing; Adjust the relative position between the template and the printed circuit board.

Four. There are burrs on the edges and surfaces

Cause of occurrence: It might be that the viscosity of the solder paste is too low and the wall of the holes in the template is rough.

Avoidance or solution: Select solder paste with slightly higher viscosity;Check the etching quality of the holes in the template before printing.

V. Fall.

Cause of occurrence:1The pressure of the scraper is too high.2The printed circuit board is not firmly positioned.3The viscosity of the solder paste or the metal content is too low.

Avoidance or solution: Adjust the pressure; Fix the printed circuit board from the beginning; Select solder paste of appropriate viscosity.

Six. Incomplete printing

The causes are:1The openings are clogged or some solder paste is stuck to the bottom of the template;2The viscosity of the solder paste is too small.3There are larger-scale metal powder particles in the solder paste.4The scraper is worn out.

Avoidance or solution: Clean the openings and the bottom of the template; Select solder paste with appropriate viscosity and ensure that the solder paste printing can effectively cover the entire printing area. Select solder paste whose particle size of the metal powder corresponds to the size of the opening hole. Check and replace the scraper.

SMTMost of the problems that occur in the solder paste printing during the surface mount technology (SMT) processing in factories are the above-mentioned types. Let the advanced solder paste technology of JJY help you solve the problems of solder paste printing! If you have any other questions, please feel free to consult us to learn more about professional solder paste solutions!