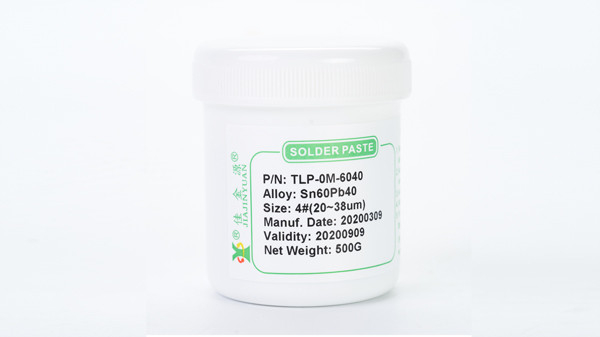

There is lead solder pasteYes.SMTIt is an indispensable soldering material in the processing industry, composed of a mixture of soldering flux components and alloy components. Among the alloy components, tin and lead are the main components, so it is called leaded solder paste. ThroughoutSMTIt plays a very important role in the processing and is crucial for the reliability of the soldering between the pads and components.

1. The purpose of the lead solder paste process

It is necessary to ensure that the surface mount components are inPCBThe corresponding pads on it have good electrical connection and sufficient mechanical strength, and an appropriate amount ofSn/PbApply the solder paste evenlyPCBOn the solder pad.

Second, there are technical requirements for lead and solder paste

1The amount of solder paste added should be uniform and consistent. The pad graphics should be clear, and adjacent graphics should not stick together as much as possible. The shape of the solder paste should match the pad to avoid misalignment.

2Under normal circumstances, the amount of solder paste per square millimeter on the pad should be controlled at approximately0.8Milligrams. For narrow-pitch components, it should be0.5mg/㎜2Left and right.

3The solder paste printed on the substrate can have a certain degree of deviation, but it must be ensured that the area covered by the solder paste for each pad reaches the required level75%Or above, when using the no-cleaning technology, it is required that all the solder paste be located on the pad.

4After printing, there should be no severe sagging, the edges should be neat, and the misalignment should not exceed0.2㎜For the pads of narrow-pitch components, the misalignment shall not be greater than0.1㎜The surface of the substrate must not be contaminated. A no-cleaning process should be adopted. The size of the template opening can be reduced to ensure that all the solder paste is located on the solder pad.

Iii. Usage Method

1Leaded solder paste must be warmed up before use25℃During the warming process, heating is strictly prohibited. Just place it at room temperature. Meanwhile, after warming up, it should be stirred manually3~5Stir for minutes or with a blender1~3Minutes.

2"Will"2/3The amount of solder paste should be inverted on the steel plate and added in small amounts and multiple times according to the production situation.

3The solder paste after opening should be in24Use it up within hours. Try not to put the solder paste that has been poured out back into the solder paste can.

4After printing the solder paste on the substrate, we suggest that you4-6Mount the components within hours and perform reflow soldering to complete the entire soldering process.

5During the solder paste soldering process, to achieve better soldering results, the indoor temperature should be controlled at22~28Celsius, humidityRH40%~60%.

6It is recommended to use ethanol.IPAClean the substrate with printing errors.

Iv. Precautions for Use

1Each time you use solder paste, only take out enough solder paste and immediately close the bottle cap.

2After the inner cover is closed, apply force to press down to squeeze out the air, and then cover the large outer cover.

3Do not stir when the surface of the solder paste has formed a skin and become hard. It should be removed. Before the next use, it should be tested and found qualified before use.

4Take out the excess solder paste and recycle it specifically in another bottle. Meanwhile, follow the precautions2Save.

5The removed solder paste should be put into printing use as soon as possible, and the process should be carried out continuously without any intermittent printing.

Shenzhen JJY Industrial Technology Co., Ltd. mainly operates:LEDType solder paste, lead-containing solder paste, lead-containing silver solder paste, stainless steel plate type solder pasteSMTSolder paste and wire manufacturers of type solder paste, lead-free flux paste, no-clean solder wire, lead-free solder wire, leaded solder wire, lead-free and leaded solder rods, wave solder rods, automatic solder wires, etc.