1.There is lead solder pasteThe reasons for short circuits in welding:

The first thing to consider isPCBIt is necessary to determine whether there is any residual leakage on the board. Therefore, the first step is to check if there is any leakage when using solder with lead solder paste.

AfterPCBAfter drilling and soldering the board, whether it is cleaned or not, if there is a leakage of electricity, it may be caused by several factors.

1,PCBThe board is broken. It has already short-circuited itself. Regarding this,PCBThe pre-welding test can be conducted before the board is used.

2It was not cleaned thoroughly. Additionally, it is necessary to clarify whether the cleaning agent used will cause corrosion or leave any residue.

PCBThe distance between the solder joints of the board should not be too close, and the frequency of power supply between the solder joints is also a factor that needs to be considered for leakage.

When the solder joints are closely clustered or the current frequency between the solder joints is very high, to achieve the best soldering effect, it is recommended to use lead-free solder wire or rosin core solder wire. After soldering, cleaning should be carried out.

Leakage of electricity may be related to the insulation resistance of the electrical appliance itself. The smaller the insulation resistance of the electrical appliance, the greater the possibility of leakage. The insulation resistance of different types of lead and solder pastes varies due to the different active agents in them.

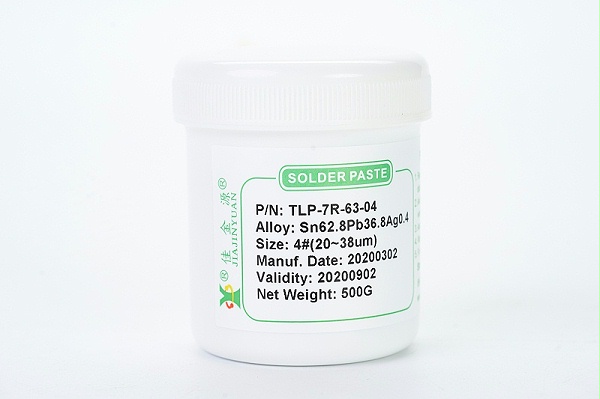

Therefore, it is necessary to choose leaded solder paste of superior quality and good activity. JJY has lead solder paste, allowing you to use it with peace of mind.

Ii. Analysis of the climbing property of lead solder paste

When it comes to lead-containing solder paste, solder climbing is one of the standards for evaluating its quality. A good solder climbing effect can make the soldering operation smooth and the appearance excellent after soldering, while a poor solder climbing effect will lead to adverse results. Therefore, for leaded solder paste, the solder climbing effect is a key factor in measuring its quality.

Whether solder paste is good or not can be analyzed from the following aspects:

1The printing quality of solder paste that has not been treated in the soldering furnace for a long time may be affected, or the quality may decline due to the solder paste being stored for too long, or it may be caused by insufficient solder leakage due to the steel mesh opening being too thin.

2Check the peak temperature. If the temperature has been reached, it means the material has oxidized.

3From the two aspects of poor raw materials, the possible causes are oxidation or moisture. It is also necessary to check whether the furnace temperature has changed.

4The main reason is the oxidation of the components. The second reason is that the expired solder paste reduces the activity of the flux, resulting in the situation where the originally well-soldered areas now have false soldered. Try changing to a new can of solder paste that hasn't expired first.

5First, it is necessary to check whether the raw materials have oxidized or if it is due to insufficient melting temperature and time for tin.