QFNIt means square flat pin-less package, yesSMTOne of the packaging types of surface mount components. Why?QFNThe solder pads on the side areSMTAfter the surface mount technology (SMT) processing and soldering, if the solder is not applied or the solder climbing height does not meet the customer's requirements, this isSMTThe problems that people have long been struggling with and worrying about. Next up is Jia JinyuanSolder paste manufacturerExplain it.QFNWhy is it difficult to tin the side? How to solve it? Hope it can be of some help to you!

MoreSMTPractitioners, due to the rigor of processing techniques, believe thatQFNThe solder climbing on the side pads should be in accordance withQFPThe soldering is considered normal only when the pins are fully tinned. AndQFNIf the exposed copper on the side is not covered by solder, it indicates an abnormal soldering. In fact, this is also incorrect.QFNThe tin coating is mainly determined by the soldering effect at the bottom of the main body. As for the amount of tin coating on the side, it is generally the customer's requirement.QFNThe requirements for solder climbing on the side pads are divided into three grades;1The level isQFNThe bottom of the solder pad is filled with tin for obvious wetting.2The grade is of the height of the side pad25%;3The grade standard is for the height of the side pads50%;

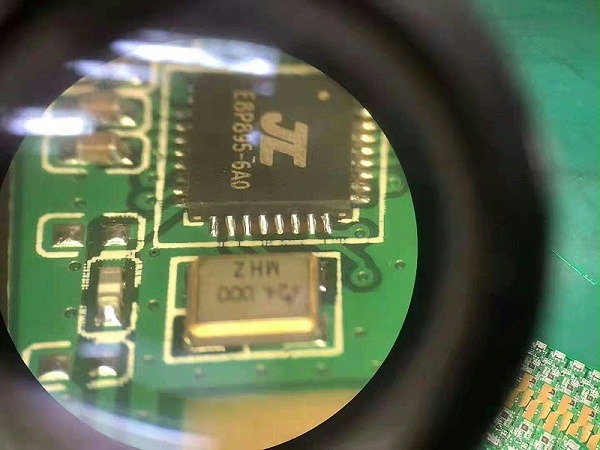

1.QFNWhy is it difficult to tin the side?

BecauseQFNThe welded ends of the side pins are all bare copper, and copper undergoes a chemical reaction in the air2Cu+O2=2CuOCopper oxide is produced. It is well known that there is a surface treatment method similar to this phenomenonPCBIt is called "bare copper plate". Its characteristic is that it is easily affected by acid and humidity and cannot be stored for a long time. After opening, it needs to be restored4Use it up within hours; otherwise, the copper exposed to the air will oxidize, thereby affecting the welding quality. Similarly, if it must be requestedQFNIf there is tin crawling on the side, it must be controlledQFNThe time after the copper is exposed on the cut surface, and due toQFNManufacturing andSMTThe transportation and storage time between surface mount technology (SMT) processing is much longer than that4However, it is unrealistic to expect a good tinning effect.QFNThe real reason why the side is not tinned isQFNThe side pins are cut. After cutting, the surface is not treated with soldering aid and has an oxide layer.

Ii. Solutions

1The steel mesh opening method of internal cutting and external pulling can be appropriately adopted. The internal cutting reduces the cross-cutting size at the pad position, thereby reducing the occurrence of problems such as solder connection and bridging during the welding process. Meanwhile, extend outwardQFNThe openings of the steel mesh at the position of the chip pads have been increasedQFNThe amount of solder paste for the pins to ensure there is sufficient solder during the soldering process;

2Choose lead-free and environmentally friendly processesQFNSolder paste for chip packaging soldering. ChooseQFNSpecial halogen-free and lead-free high-temperature solder pasteLFP-JJY5R1-305T4The powder number can be selected for use4In the process of steel mesh printing, a large amount of tin is added, which is helpful for tin climbing to a certain extent.

3,QFNWhen the tin coating on the side is not good, it can be doneSMTBefore reflow soldering in surface mount processing, adding an appropriate amount of flux paste around the periphery will significantly improve the soldering solder crawling effect.

The above content is provided by Shenzhen JJY Solder Paste Manufacturer. If you need to know more about itSMTFor knowledge related to surface mount technology (SMT) processing, please feel free to consult JJY15For many years, we have been dedicated to the research and development, production and sales of solder paste, solder wire, solder bar, flux paste and other solder materials, providing customers with a complete set of electronic soldering solutions.