With the rapid development of component packaging, more and morePbga,Cbga,CCGA,QFN,0201,01005Resistors and capacitors, etc. have been widely used, and surface mount technology has also developed rapidly accordingly. In its production process,Solder pastePrinting forPCBAThe influence and role of processing the entire production process are receiving increasing attention from engineers. In the industry, enterprises also widely agree that to obtain better soldering and long-term reliable products in terms of quality, the first thing to pay attention to is the printing of solder paste. Today, Shenzhen JJY Solder Paste Factory will explain it to youPCBAWhat are the factors to consider when choosing and processing solder paste?

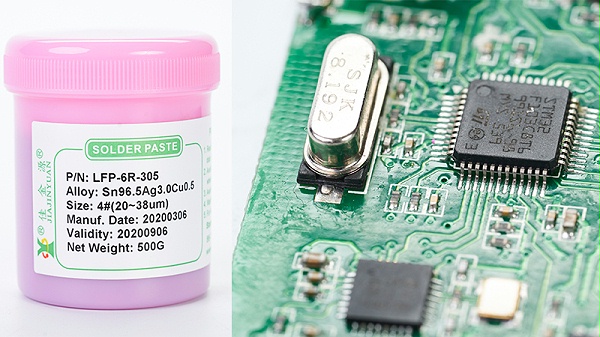

Solder paste is much more complex than a simple tin-lead alloy. Its main components are as follows: solder alloy particles, flux, rheological modifier, viscosity controller, solvent, etc. Make sure to master the relevant factors and choose different types of solder paste;At the same time, it is necessary to choose a solder paste manufacturer with a complete product manufacturing process and stable quality. When choosing solder paste, the following factors should usually be noted:

1The viscosity of solder paste

The viscosity of solder paste is the most important factor affecting printing performance. If the viscosity is too high, the solder paste is difficult to pass through the openings of the template, resulting in incomplete printed lines. If the viscosity is too low, it is prone to flowing and edge collapse, affecting the resolution of printing and the flatness of the lines.

The viscosity of solder paste can be measured by a precise viscometer. In actual work, during normal production, a simple method can be used to qualitatively determine the viscosity: lift the solder paste with a spatula and see if it drops slowly and section by section until the viscosity is moderate. Meanwhile, we also believe that to ensure that the solder paste has excellent viscosity characteristics each time it is used, the following points need to be achieved:

I. From0℃During the process of restoring to room temperature, the sealing and time must be guaranteed;

Second, it is best to use a dedicated mixer for stirring;

Third, the production volume is small and there is a situation of repeated use of solder paste. Strict regulations need to be formulated. Solder paste outside the regulations must be strictly stopped from being used.

2The stickiness of solder paste

The viscosity of the solder paste is insufficient. During printing, the solder paste will not roll on the template. The direct consequence is that the solder paste cannot fully fill the holes in the template, resulting in insufficient solder paste deposition. If the viscosity of the solder paste is too high, it will stick to the wall of the template hole and cannot be completely imprinted on the pad.

The selection of solder paste viscosity generally requires that its self-adhesive ability be greater than its bonding ability with the template, while its bonding force with the template hole wall is less than its bonding force with the pad.

3The uniformity and size of solder paste particles

The particle shape, diameter size and uniformity of solder paste solder also affect its printing performance. Generally, solder paste with fine particles has better clarity of solder paste print strips, but it is prone to edge collapse and has a higher chance of oxidation. Generally, the pin pitch is taken as one of the important selection factors, while taking into account both performance and price.

JJY solder Paste Manufacturer mainly engages in lead-free solder paste.SMTSurface mount solder pasteLEDResearch, development, production and supply of solder pastes, lead-free solder wires, wave soldering rods and other solder solders. For more knowledge about electronic soldering, please contact us. Welcome to interact with us.