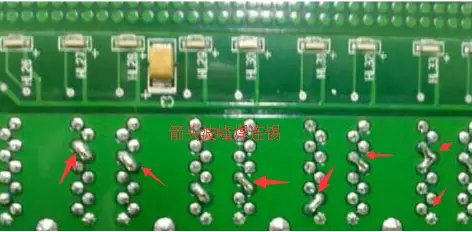

In the electronics manufacturing industry,SMTProcessing is a complex technical activity that requires high precision. During this process, continuous soldering is a common but serious problem, which may damage the performance and stability of the entire circuit board. As a professional Shenzhen JiajinSource solder paste manufacturerWe are quite clear about the severity of the continuous welding problems encountered by many customers and actively seek solutions. So, how is continuous welding carried outSMTWhat happened during the processing?

First of all, we need to pay attention to the influence of welding temperature and time. These two parameters areSMTIt plays a crucial role in processing. When the temperature is too high or the welding time is too long, the solder may flow, thus causing unnecessary connections, which is what we call continuous soldering.

Secondly, the design of the pad and the selection of solder paste will also affect the occurrence of continuous soldering. For instance, if the pad spacing is designed too narrow, the stability will be compromised. The stability and precision of the surface mount technology (SMT) machine, as well as the consistency of the soldering process, will directly affect the occurrence rate of continuous soldering. Problems such as equipment aging and process parameter drift may all lead to the occurrence of continuous welding issues.

Finally, we cannot ignore the human factor. The skills and experience of the operators directly determine the quality of welding. Operators with insufficient skills or experience are more likely to cause problems such as continuous welding.

Overall, continuous welding isSMTCommon but inevitable problems in processing. To avoid continuous welding, we not only need to strictly control every production link, but also constantly improve the skills and experience of our employees.

As a 16-year-old veteran solder paste manufacturer, JJY has been dedicated to the research and development as well as production of solder paste for many years. Our solder paste is of stable quality, without solder disconnection, false soldering or monument erection. No residue, Wuxi beads, bright and full solder joints, firm solder joints, and excellent electrical conductivity. If you have any needs, please feel free to contact us.