With the emergence and development of microelectronic products, the requirements for circuit boards of electronic products are becoming increasingly precise. inSMTDuring the surface mount technology (SMT) process, the components stand sideways after reflow soldering(It is usually a resistance-capacitance component)It is called setting up a monument. JJYSolder paste manufacturerI will share with you the reasons for setting up the monument and the corresponding solutions:

1.PCBDesign reasons

1,PCBThe design of the pad size is irregular. For instance, the pad design area is usually too large on the side connected to the ground wire, resulting in uneven heat capacity at both ends of the pad or different amounts of solder paste.

2,PCBThe layout of the surface components in the design is unreasonable, resulting in uneven heat absorption on both sides of the component pads. For example, large structural componentsBGAEncapsulationQFPFor devices with high heat absorption, the temperature on both sides of the small chip component pads around them will be uneven, resulting in uneven soldering tension when the solder paste dissolves.

3,PCBWe often see that the pad spacing in the design is too large in the actual production process, and the probability of this situation occurring is very high.

Ii. Component reasons

1Oxidation of the soldering coating at both ends of the component pins causes the solder paste to have different wetting forces. When two different wetting forces are generated, wetting deviation or cracking will occur.

Iii. Reasons for equipment parameters

1Solder paste printing misalignment: If the solder paste printing is offset and not fully deposited on the solder pad, this may cause the component terminals to fail to effectively contact the solder paste, or they may not come into contact with the solder paste at all or only have a small amount of contact. All these are highly likely to cause monument erection or offset problems.

2The solder paste was applied too thickly. After the solder paste melted, the components floated up. In this case, components are very likely to experience the phenomenon of being exposed to hot air.

3Insufficient mounting pressure causes the components to fail to make effective contact with the solder paste. During the reflow soldering process, the pins do not get wet, resulting in deviation and the formation of cracks.

4If the placement position of the surface mount machine is offset, it may cause a monument to stand. If the solder paste cannot fully contact the two pins of the component, resulting in a difference in wetting between the two ends, a monument or offset may occur.

Iv. Solutions

1It is proposed based on the problems that occur during the manufacturing processDFMImprovement report, requirementsPCBThe supplier optimizes the pad design, classifies the design layout, and arranges the equipment clearly and reasonably.

2When conditions permit, timely replacement of the oxidized material at the pins can reduce the occurrence of adverse situations. If the materials are not replaced, the defects should be reduced in time by optimizing the furnace temperature curve.

3CombinePCBThe size, thickness, component layout, and solder paste furnace temperature curve have been optimized to create a furnace temperature curve suitable for each product. Minimize the defect rate.

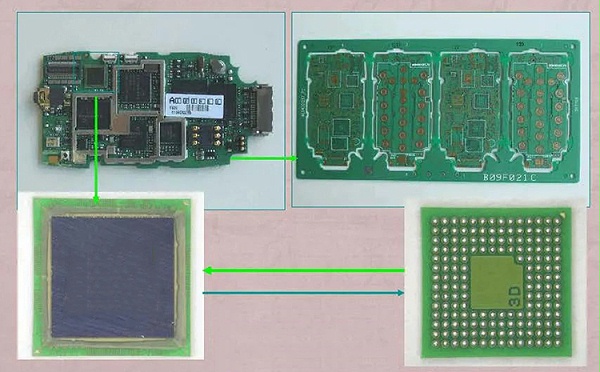

4Confirm the size of the opening of the steel mesh and the thickness of the steel mesh, and do it according to the welding points of the erected monumentSIP(3DControl by solder paste detector.

5Timely readjust the placement pressure of the surface mount machine, the component suction coordinates, and the placement coordinates.

As a 15-year-old veteran solder paste manufacturer, JJY has been dedicated to the research and development and production of solder paste for many years. The quality of the solder paste is stable, without solder bonding, false soldering or establishing a reputation. No residue, Wuxi beads, bright and full solder joints; The weld points are firm and have excellent electrical conductivity. If you have any needs, please feel free to contact us.