Solder pasteWelding, as a bridge connecting electronic components and circuit boards, is of self-evident importance. However, when encountering problems such as solder paste not being soldered or missing solder, it not only affects production efficiency but may also deal a fatal blow to product performance. Today, JJY Solder Paste Manufacturer will give you an in-depth analysis of these soldering problems:

Analysis of the Reasons for Solder Paste Not being soldered:

First, it might be that the solder paste has been used for a long time and has expired, affecting its quality. It could also be that the steel mesh is too thin, resulting in insufficient solder leakage.

Second, check the peak temperature. If the temperature has been reached, it indicates that the material has oxidized.

Iii. Analyze from two aspects:1The raw materials are of poor quality. The reasons lie in oxidation or moisture.2Whether there is any change in the furnace temperature;

Fourth, the main issue is the oxidation of components. Secondly, if the solder paste expires, the activity of the flux will decrease, and even if the solder was soldered before, it will now have a false solder. You can try a new can of solder paste first;

V. First, check whether the raw materials have oxidized. It might also be due to insufficient temperature and time for tin melting.

Analysis of the Causes of Missed Solder Paste Soldering:

1,PCBThe design of the board surface is not reasonable enough, and missed soldering occurs due to the shadow effect during soldering. At the very beginning of the design, the layout and arrangement direction of components should be taken into account, and the principles of placing small components in front and avoiding mutual obstruction as much as possible should be followed to ensure that it is reasonable, convenient and simple.

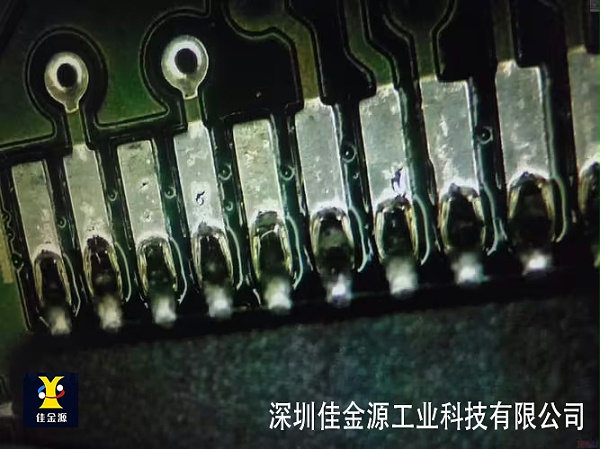

2The peaks are not smooth, and the heights of the peaks on both sides are inconsistent. For instance, if the solder nozzle of a wave soldering machine is blocked by oxide, it will cause the wave soldering to have a sawtooth shape. At this time, it is very easy to cause missed soldering or false soldering. The wave peak nozzles should be cleaned in time.

The problems of solder paste not being soldered and missed soldering may seem complex, but in fact, as long as one starts from aspects such as material selection, process control, and operational details, the key to solving the problems can be found. Shenzhen JJY owns16With years of experience in research and development and production, we have a strong technical force and stable product quality. Flagship products:QFNHigh solder climbing rate solder paste, zero halogen solder pasteVOIDLow-porosity solder paste, laser solder paste, water-washed solder paste, and high-reliability ones used in military, aerospace, power, photovoltaic and other industriesSn62Pb36Ag2Solder pasteSn62.8Pb36.8Ag0.4Solder paste6337Solder paste, transparent and colorlessLEDHigh-brightness anti-monument solder pastemini-LED/micro-LEDDie bonding solder paste, high-reliability lead-free low-temperature solder paste, low-temperature solder paste for heat sinks, lead-free medium-temperature solder paste, lead-free high-temperature0307/105/305Solder paste, etc. Proprietary technology, strict quality control, continuous stability, making customers worry-free, efficient, cost-effective and competitive!