JJYSolder paste manufacturerWhat is the role of temperature in welding? With the continuous development of industrialization,The requirements for welding technology are also getting higher and higher,The welding temperature is one of the important process parameters in the production of welded pipes,It can not only have a direct impact on the welding quality,Everyone knows that there are countless brands and manufacturers of solder paste. But what kind of solder paste manufacturer can have good performance in use,Many people want to know the working temperature range of the board after solder paste soldering, such as below zero50The range from degrees to what degree, let's have the editor explain it to you below:

The effect of temperature on welding.

Solder paste is an auxiliary raw material in the entire soldering process. It can be used under high-temperature conditions during the soldering process and can also exist in a wide range of forms between liquid and liquid in metal particles. Among them, copper and silver can improve the ignition efficiency. Due to the high-temperature resistance of the welded product, it can withstand the high-temperature welding of the welding machine during the welding process.

When the solder paste is in an electrically heated condition, its flow back is divided into five links.

Firstly, the organic solvent used to achieve the required viscosity and the characteristics of the screen printing ink volatilizes, and the temperature rise must be slow(Approximately every second3℃To limit boiling and splashing, avoid Small tin beads are also produced. Some components are very sensitive to internal ground stress. If the external temperature of the component rises too fast, it will cause cracking.

Flux activity, the gradual chemical water treatment behavior, water-soluble flux and non-rubbing flux will both produce the same cleaning action, only the temperature is slightly different. Hydroxides and some environmental pollutants from the metal materials to be fused

Remove from solder particles. A good solder joint in metal materials science specifies a "cleaned" surface.

When the temperature rises again, the solder particles melt independently first, and then gradually vaporize and absorb tin on the surface, which is the "lamp-like" process. Then cover it on any possible surface and gradually form solder spots.

This stage is crucial. When all the solder particles of a component melt and fuse together to form liquid tin, the surface support force gradually forms on the surface of the solder hole. If the component pins are in the same positionPCBThe gap of the weld layer exceeds4milIt is highly likely that the surface support force will cause the foot position and the solder layer to separate, resulting in solder spot guidance.

During the cooling process, if the cooling is fast, the compressive strength of the solder dots will be slightly greater, but it cannot be too fast to cause temperature stress inside the components.

Welding is highly efficient.

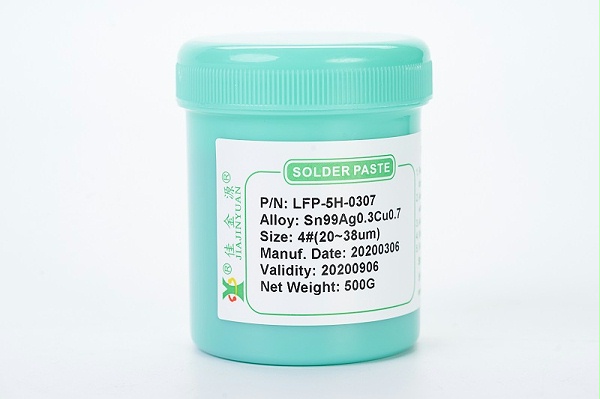

Non-heavy metal solder paste is an auxiliary raw material for soldering. In the application process, it can play an effective auxiliary role in the soldering steps. Because silver and copper have high heat conduction efficiency and work diligently; Therefore The solder paste is made into a heavy metal-free solder paste, in which the lead metal is replaced by silver and copper. In order to better create an aesthetically pleasing design for the soldered products, and at the same time evenly apply solder paste to the surface of the solder joint, silver and copper metals can be combined with tin metal for application, making the solder paste present a liquid similar to mud.

Shenzhen JJY has carried out mutually beneficial cooperation with electronic raw material producers. At the same time, it also manufactures solder wires and solder rods for other enterprises.Solder pasteProduction of solder paste With a rich variety of successful cases in the research and development of chemical raw materials, our overall strength has created a sales market that is of high quality and honest and trustworthy.