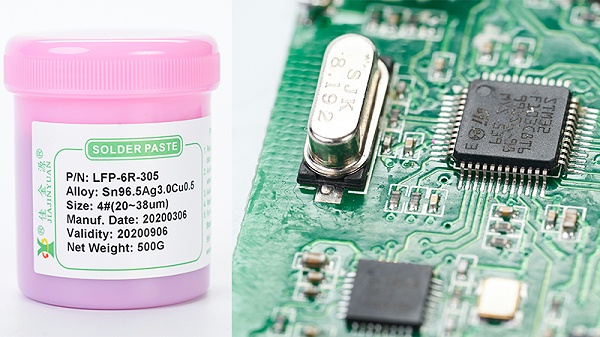

SMTA very important processing raw material in surface mount technology (SMT) processing is solder paste.Solder pasteThe quality will be directly affectedSMTThe quality of the processed solder joints, in turn, affects the quality of the entire electronic processing product. Well,SMTWhat are the requirements of surface mount technology (SMT) users for solder paste? Now, JJY solder Paste Manufacturer will introduce it to youSMTThe common requirements of surface mount technology (SMT) users for solder paste:

1Solder paste has a shelf life, and its viscosity will also change over time. During the warranty period, it is necessary to ensure that the viscosity changes stably and that there is no separation between the solder powder and the flux.

2The solder paste should have good printability, demolding property and solderability, and at the same time, there should be no phenomenon of overflow adhering around the opening of the template.

3The corrosion resistance and air insulation of the flux must meet the requirements and standards of electronic processing, and it must not be toxic.

4The flux residue should have good solubility and cleaning performance.

Shenzhen JJY Industrial Technology Co., Ltd. is a company15As a manufacturer specializing in the research and development and customization of solder paste, lead-free solder paste and leaded solder paste for many years, if you want to learn more about solder paste, please continue to follow the online message of JJY Solder Paste Factory to interact with us.