SMTSurface mount technology (SMT) sampling, asPCBThe key steps after the board design involve a series of meticulous technological processes. During this process, design preparation is of vital importance, covering material screeningPCBIt covers multiple aspects such as precise design and size control, layer planning, material selection, and surface treatment. The core of these preparations lies in in-depth considerationPCBThe functional requirements and reliability requirements of the board lay a solid foundation for the subsequent sample-making process. Now, let's have JJY solder Paste Manufacturer explain itSMTWhat are the precautions for surface mount technology sample making?

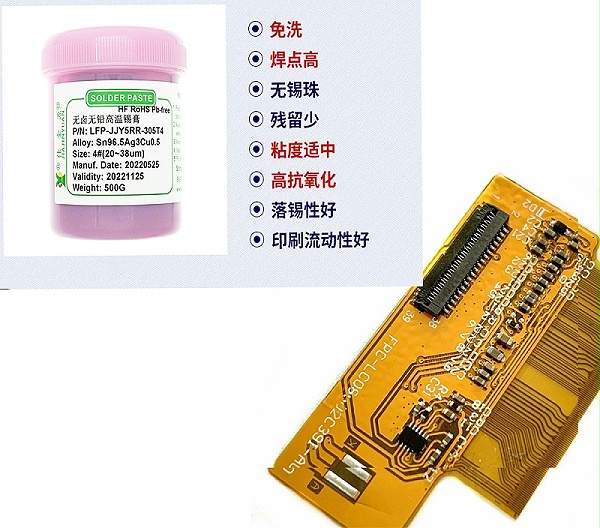

Talk aboutSMTSoldering is undoubtedly one of the core steps in surface mount technology (SMT) prototyping. In this stage, we usually operate with an automatic welding machine to ensure the accuracy and efficiency of the welding. To achieve high-quality welding, factors such as the shape and size of the solder pad, as well as the treatment of the weld points, all need to be carefully considered.

Immediately following the welding is the inspection stage. In order to ensurePCBThe connection performance of the board and the circuit functions meet the standards. We rely onX-RayProfessional tools such as detectors and circuit detectors, rightPCBAA comprehensive and meticulous inspection of the circuit board is carried out.

The testing stage should not be ignored either. At this stage, we use tools such as testers and test programs. YesPCBAThe circuit board undergoes a comprehensive test. The aim is to ensure the reliability and stability of its functions, thereby providingSMTThe overall quality of surface mount technology (SMT) prototyping is guaranteed.

Finally, packaging serves asSMTThe final stage of surface mount technology (SMT) prototyping also requires meticulous operation. We use a variety of materials such as electrostatic bags, cartons and paper boxes, and combine themPCBABased on the size and characteristics, meticulous packaging treatment is carried out to ensure the safety and integrity of the product during transportation and storage.

To sum up,SMTSurface mount technology (SMT) prototyping is a complex process involving multiple steps, from design preparation to soldering, inspection, packaging, testing and packaging. Each step must be strictly controlled to ensure the quality and performance of the final product.

Let Jia Jinyuan'sSolder pasteTechnology will assist you in solving itsmtThe problem of how to manage solder paste printing in proofing! If you have any other questions, please feel free to consult us to learn more about professional solutions for solder paste!