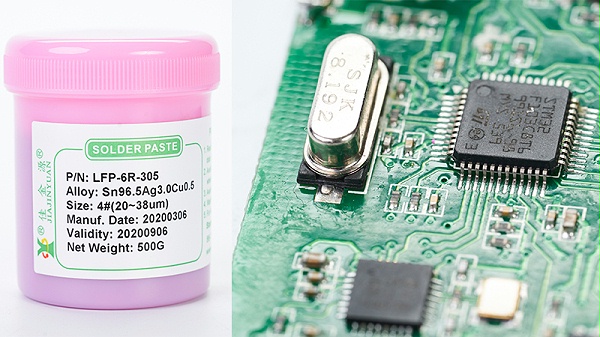

SMTSurface mount technology (SMT) is currently one of the most common mounting techniques in the electronics industry, throughSMTTechnology can mount more, smaller and lighter components, enabling circuit boards to meet the requirements of high precision and miniaturization. Of course, this is correctSMTSurface mount technology (SMT) processing has higher and more complex requirements, so there are many matters that need attention during the operation process. Now, let's talk about it from JJY solder Paste Manufacturer:

1.SMTPrecautions for the use of solder paste in surface mount processing:

1Storage temperature:It is recommended to store in the refrigerator at a temperature of5℃-10℃Please do not lower than0℃.

2Outbound principle: The first-in, first-out principle must be followed. Do not allow solder paste to be stored in the cold storage for too long.

3Thawing requirements: Thaw the solder paste naturally after taking it out of the freezer at least4The bottle cap should not be opened when thawing after one hour.

4Production environment: It is recommended that the workshop temperature be25℃±2℃,Relative humidity45%-65%RHIt should be used under certain conditions.

5Used old solder paste: It is recommended to keep the solder paste after opening the lid12Use it up within hours. If you need to store it, please put it in a clean empty bottle, then seal it and store it back in the freezer.

6The amount of solder paste placed on the steel wire mesh: The amount of solder paste placed on the steel wire mesh for the first time should not exceed the height of the squeegee when printing and rolling1/2It is advisable to observe frequently, increase the frequency frequently and reduce the amount.

Ii.SMTPrecautions for printing operations in surface mount technology:

1Scraper: It is best to use a steel scraper, which is conducive to printingPADThe solder paste on it is formed and demolded.

Scraper Angle:Manual printing45-60Degree of;Machine printing60Degree.

Printing speed:"Artificial"30mm-45mm/min;Printing press40mm-80mm/min.

Printing environment:The humidity is23℃±3℃,Relative humidity45%-65%RH.

2Steel mesh: The thickness of the steel mesh and the shape and proportion of the holes are selected according to the requirements of the product.

QFPCHIPThe center distance is less than0.5mmand0402theCHIPLaser drilling is required.

Steel mesh inspection: A tension test of the steel mesh should be conducted once a week,The tension value is required at35N/cmThat's all.

Clean steel mesh:In continuous printing5-10slicePCBWhen board,Wipe it once with dust-free mesh paper. It's best not to use rags.

3Cleaning agent:IPASolvent: It is best to use when cleaning steel meshIPAWhen using alcohol solvents, do not use solvents containing chlorine components, as these solvents will damage the components of the solder paste and affect the overall quality.

JJYSolder pasteThe manufacturer mainly engages in lead-free solder paste.SMTSurface mount solder pasteLEDResearch, development, production and supply of solder pastes, lead-free solder wires, wave soldering rods and other solder solders. For more knowledge about electronic soldering, please contact us. Welcome to interact with us.