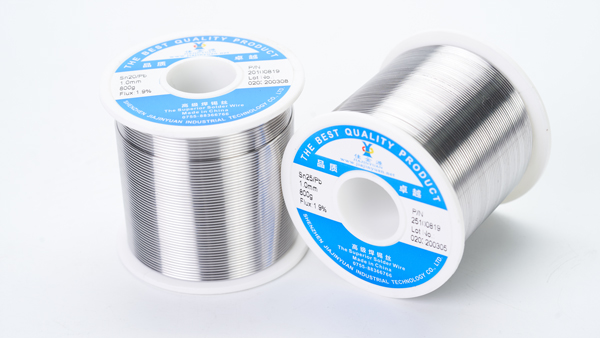

In the manufacturing process of power batteries, the selection of welding methods and processes can directly affect the quality, safety and cost of the batteries. Whether it is the poor quality of the selected solder material or the mismatch between the solder material formula and the product to be soldered, this will cause a series of soldering problems. For instance, excessive cooling rate, low material cleanliness, low material purity, and poor material properties are all prone to collapse and spatter during the welding process, which reduces the performance of the welded joint. whileJJYThe produced solder materials effectively avoid these problems.

The welding process requirements for power batteries are extremely strict. Different production processes and different welding parts adopt different welding methods. With the in-depth development of the power battery industry, higher demands have been put forward for the assembly and welding accuracy and quality of batteries.JJYWith a dedicated R&D team, we can offer optimization suggestions for the welding process of batteries, further enhancing the product quality of power battery enterprises and improving the safety and service life of power batteries.

Shenzhen JJY Industrial Technology Co., LTDEstablished in2008years10Yue is a customized solder solution provider integrating the research and development, production customization and solution services of electronic solder (solder paste, solder wire, solder bar, etc.). The brand "JJY" it operates has been selected into the Brand Power Demonstration Project [Solder Materials]. If you are interested in consulting, please feel free to call us for negotiation!