inSMTIn surface mount technology (SMT) processing, the quality requirements for solder joints are extremely strict.PCBADuring the welding process, various factors such as operational errors, welding techniques, and welding materials may sometimes lead to poor welding. The following is JJYSolder paste manufacturerHere is a brief introduction to some common welding defects and their causes:

1Excessive residue on the board surface: Generally, it is due to the fact that the soldering before the surface mount processing was not preheated or the preheating temperature was too low, resulting in insufficient temperature of the tin furnace. The speed of moving off the board is too fast. Excessive application of flux; During the use of flux, no thinner was added for a long time. The incorrect ratio between the component feet and the orifice plate leads to factors such as flux accumulation.

2The main reason for these phenomena is that the components turn green and the solder pads turn blackSMTThe preheating before surface mount processing was not sufficient, resulting in excessive flux residue and too many harmful substances remaining. The flux that needed cleaning was used, but it was not cleaned after the welding was completed.

3False soldering: This is a relatively common processing defect phenomenon.PCBAThe occurrence of false soldering during processing also has a relatively significant impact on parameters such as the product's usage and reliability. The main causes of false soldering in electronic processing include uneven or insufficient application of flux, unreasonable wiring, blockage of foaming tubes, uneven foaming, uneven application of flux, severe oxidation of some pads or solder feet, incorrect operation methods during hand-soldering, and uneven wave peaks, etc.

4Cold welding: Generally, it is due to insufficient welding temperature or the vibration of the workpiece before the solder solidifies. This kind of poor solder joint has low strength and weak electrical conductivity. When subjected to external forces, it is very likely to cause short circuits in components.

5The solder joint turns white: The main reason for this phenomenon is usually that during the manual soldering process, the temperature of the soldering iron is too high or the heating time is too long. This kind of poor solder joint is not strong enough. When subjected to external force, it is very likely to cause a short circuit of components.

6Pad peeling: The main reason isSMTDuring the surface mount technology (SMT) processing, the solder pads, after being exposed to high temperatures, exhibit andpcbThe phenomenon of board peeling, such poor solder joints can easily cause short-circuit faults in components.

The formation of tin beads is generally due to the preheating temperature being too low, failing to achieve the preheating effect. The speed of moving off the board is too fast. The inclination Angle of the chain is not good. The operation method when tin immersion by hand is incorrect. Tin beads are produced after the bubbles burst. Caused by reasons such as a damp working environment;

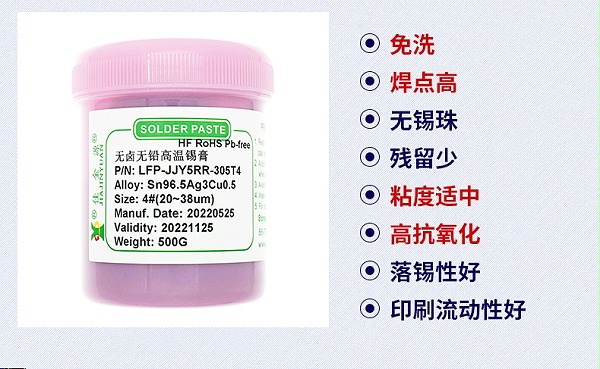

JJY, as a company that owns15A solder paste manufacturer with a history of many years, it has been committed to the research and development, production and sales of solder paste. The quality of the solder paste is stable, but it does not attach solder. It is not worth soldering and is not worth establishing a monument. Wuxi beads remain, the weld points are bright and full, the welding is firm, and the electrical conductivity is good. If you have any needs, please feel free to contact us.