Wave soldering is actually the process of jetting molten solder through an electromagnetic pump into the solder specified in the design plan.Solder paste manufacturerIt can also be produced by adding nitrogen to the solder pool. This is to complete the soft brazing of the mechanical equipment and protective grounding between the solder end of the electronic device and the solder layer of the printed circuit board according to the solder wave peak.

Wave solderingSome methods and steps. Insert the components into the corresponding component holes, and after applying flux and heating, Then comes the wave soldering cooling After removing the pins of the plugin, conduct a check.

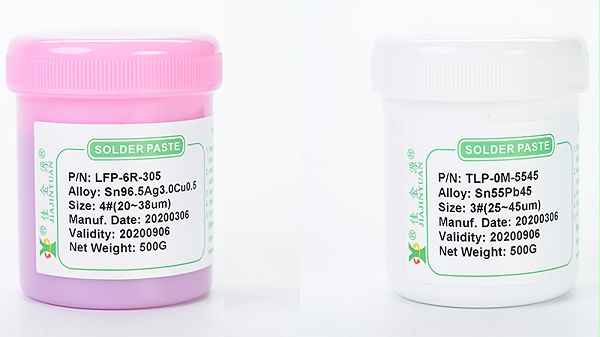

Wave soldering, along with the deepening of partners' awareness of ecological protection, has added new welding methods. Because lead is harmful to the environment and human health, lead-free processing techniques have emerged. When tin, silver and copper alloys and some specific fluxes are selected, the temperature of electric welding will also be higher.

In daily life, some electronic products such as televisions and stereos that our friends use all employ wave soldering.

Shenzhen JJY Industrial Technology Co., LTDMain business:LEDType solder pasteThere is lead solder pasteLead-containing silver solder paste, stainless steel plate type solder pasteSMTProduction of type solder paste, lead-free flux paste, no-clean solder wire, lead-free solder wire, leaded solder wire, lead-free and leaded solder bars, wave soldering bars, and automatic soldering lines.