JJY Solder Paste Manufacturer answers:There is lead solder pasteWhat technical points should be noted during printing? Generally, before applying solder paste, the steel mesh should be adjusted and the printing table and steel mesh should be cleaned thoroughly with alcohol. The height of the steel mesh fixture should be adjusted to ensure that the steel mesh is in close contact with the platform.

①Before printing leaded solder paste, it is necessary to inspect the squeegee, steel mesh and other supplies. Ensure cleanliness, free of dust and dirt (keep clean when necessary) to prevent the solder paste from being contaminated by the environment and affecting its tinning properties. The scraper opening should be vertical without any gaps. The steel mesh should be vertical and there should be no special featuresshapeChange. There must be no residual tin paste hard lumps or other dirt on the edge of the opening slot.

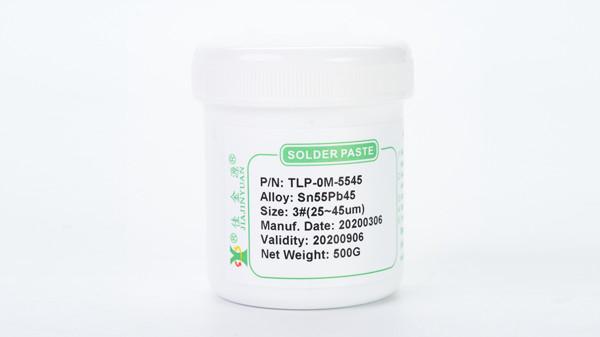

There is lead solder paste

②There should be tooling fixtures or vacuum pump equipment to fix the base plate to prevent it from being fully printedIn the process PCB It can cause offset and improve the actual separation effect of the steel mesh after printing.

③Connect the steel mesh with PCB In the middleAdjust the location to be as consistent as possible. (Gap alternating current will lead to solder leakage, and horizontal displacement will cause. The solder paste is printed outside the solder layer. ;

④ Tin needs to be added to the steel mesh at the beginning of printingThe ointment should be in appropriate amount, generally A5 Specification and model steel mesh plus 200g Up and downB5 Specification and model steel mesh plus 300g Up and downA4 Specification and model of steel mesh add 400g Up and down;

⑤As the printing work continues, the amount of solder paste on the steel screen will gradually decrease. When it reaches an appropriate level, an appropriate amount of fresh solder paste should be added.

⑥The separation rate of the steel mesh after printing should be as slow as possible.

⑦When printing continuously, the upper and lower edges of the steel screen should be cleaned at regular intervals (depending on the specific situation) to remove the solder paste adhering to the bottom edge of the steel screen to prevent tin formation Ball When cleaning, be careful not to leave any water or other residues on the solder paste or steel mesh.

⑧If the solder paste remains on the steel mesh for a long time (or the solder paste that has been recycled from the steel mesh and reused after a long period of time) Its printing characteristics and adhesiveness are very likely to decline. Add an appropriate amount 3/5Blending agent, yes Obtain the corresponding improvements;

⑨Attention should be paid to the control of temperature and humidity in the workplace. In addition, obvious gas flow should be avoided to prevent accelerating the evaporation of organic solvents and affecting viscosity.

⑩ Before the work is completed, the bottom and bottom of the steel mesh must be thoroughly cleaned (pay attention to the cleaning around the holes).

[Suggested countermeasures]Select steel meshes of different thicknesses based on whether the product has fine components, and measure the thickness of the solder paste CPKAdjust the parameters such as the support block of the printing machine, the printing speed, and the pressure of the scraper. Regularly check that the tension of the steel mesh meets the standard. Select the appropriate automatic and manual cleaning methods and frequencies for the steel mesh based on the product .

2Excessive printing offset:PCBThe fixing device is poor, and the manual or automatic positioning and correction accuracy of the machine is poor. Generally, the printing offset exceeds the limit1/4The pad above is judged as a printing offset.

[Suggested countermeasures]Adjust the fixing device of the printing machine, adjust the printing accuracy and repeatability, and increase PCBLight recognition ability.

3Solder paste edge collapse, including the following three types:

APrinting edge collapse

The viscosity of the solder paste is relatively low, and its thixotropy is poor, resulting in flow and edge collapse after printing. The walls of the steel mesh holes are rough with protrusions and depressions. During printing, tin seepage occurs, and during demolding, sharp edges are pulled out, resulting in similar edge collapse phenomena. Excessive pressure from the squeegee causes damage to the formation of the solder paste.

[Suggested countermeasures]Choose solder paste with moderate viscosity; Adopt laser cutting or other better steel mesh; Reduce the pressure of the scraper.

BEdge collapse during mounting

The placement machine is in the process of mounting SOP,QFP, QFN,CSPWhen using such components, excessive pressure can cause changes in the shape of the solder paste and lead to edge collapse.

[Suggested countermeasures]Adjust the mounting pressure and mounting height.

CEdge collapse during welding heating

The reflux preheating temperature rise was too fast, and the solvent components in the solder paste evaporated too quickly, causing the solder particles to be squeezed out of the solder area and resulting in edge collapse.

[Suggested countermeasures]According to the solder paste supplier Set the furnace temperature according to the parameters (temperature, time) in the product specification sheet .

4Fine meshing elementsPadThe position, length and width design do not match the distribution and size of the component pins.

[Suggested countermeasures]Confirm whether the combination is compatible at the beginning of the trial production of the new product PCBOr component design specifications.

Shenzhen CityJJYIndustrial Technology Co., LTD., dedicated12We have been engaged in the research and development and sales of the soldering industry for many years, providing customers with complete electronic soldering solutions. The included projects are the semiconductor research and development of solder (solder wire, solder paste, solder bar, solder sheet, tin foil) and electronic products, etc.