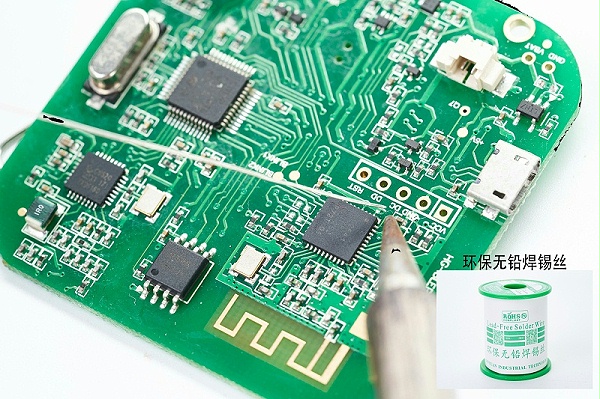

Solder wireEveryone has learned that it is a kind of soldering material, which is generally more widely used in the electronics industry. It plays a very important and significant role in the field of electronic production and can be said to be an indispensable material in the processing and production process of the electronics industry. However, what should be noted when soldering wets the substrate? The following is an explanation led by the Habiti manufacturer:

1The correct soldering method not only saves time but also prevents air pollution.

2Solder is used for connecting parts and for conducting and dissipating electricity, and is not used as a support point for force.

3Quality is established during the manufacturing process rather than through post-event quality control and maintenance. The most direct and economical way to achieve quality is through direct operation personnel, rather than through quality control and maintenance or post-event maintenance by engineering personnel.

4Welding is an art of skills, and its interest lies in everyone's attention to the welding work. Some people say that a tin worker with excellent welding skills should be called an artist of metals.

5Never touch the elements or solder the soldering iron tips. It's very hot(about400 ° C)And the burns it caused you.

6Work in a well-ventilated place. The smoke formed during soldering is mainly composed of molten solder and flux, which is quite irritating. Avoid inhalation by keeping your head to one side instead of upwards.

The above is the explanation of some knowledge content for everyone. You can take a look. Here, I would like to tell you that generally, you should pay attention to the packaging appearance of the solder wire. Although the packaging appearance does not represent the quality, some marks still need to be noted. If you want to learn more about soldering, welcome to consult!