The previous article mentioned to everyone whether the weather would be rightSolder wireCause an impact? By now, all practitioners should have a clear understanding of the situation. Here, I'd like to mention that the solder paste manufacturer has collected some small pieces of knowledge. Everyone can take a look together:

On the one hand, solder wire is welded at low temperatures. Due to the low temperature of the welding environment, the temperature gradient between the heat-affected zone of the welding and the base material is increased, which will lead to an increase in the cooling rate of the heat-affected zone.

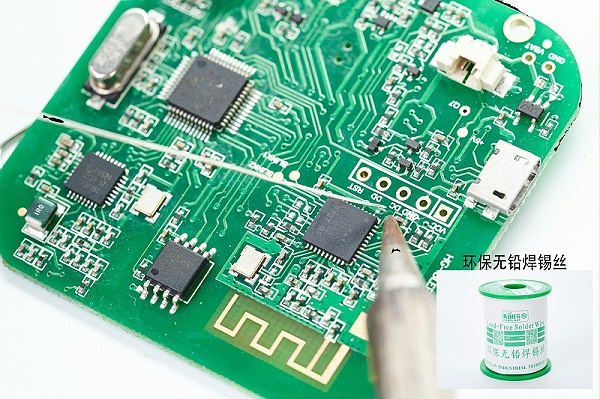

On the other hand, in regions such as Guangdong and the Pearl River Delta, soldering factories often encounter humid weather and the return of the south wind, which can cause solder wires (solder wires), circuit boards, and soldering tools to get damp due to improper storage. When soldering solder wires by hand, excessive humidity can lead to solder explosion, resulting in intermittent solder explosion or poor soldering. The phenomenon of "exploding tin" is very common during the soldering process of solder wire. "Exploding tin" refers to the evaporation of solvents in the flux adhering to the soldering material, causing the surface of the board to cool down. The air in contact with it condenses and forms mist that adheres to the surface of the board. The sudden high temperature during soldering causes the moisture to evaporate and diffuse rapidly. If the surface of the board does not have an appropriate Angle for the vapor to diffuse, it will rapidly push the soldering. Form tin frying. In simple terms, it means that when the moisture content in the air is too high, the soldering materials or tools get damp. When the solder is exposed to high temperatures during soldering, it will produce gas and cause the solder to explode. When encountering such a phenomenon, we should pay special attention to the storage and operation environment of the flux or soldering material. It is necessary to keep it dry to avoid tin explosion due to moisture.

When soldering, if the external temperature is too low, the preheating time will need to be slightly longer. If the preheating time does not reach the soldering temperature or the preheating time is too short and the temperature is insufficient, the condensed moisture on the board surface cannot be completely evaporated. Once it comes into contact with high-temperature soldering instantaneously, it will also cause soldering to explode. In addition to the tin explosion caused by the above-mentioned weather changes, improper operation, unclean surface of the soldering material, and sweat stains on the hands of the workers can also lead to tin explosion.

The temperature of the soldering iron used during soldering is also very crucial. It should be suitable for the melting point of the alloy of the soldering wire. It should neither be too high nor too low. Both excessively high and low temperatures can cause phenomena such as false soldering, solder absorption, and short circuits. The working environment temperature for soldering is also a factor to consider. Extremely hot or cold weather outside not only affects soldering but also the physical and mental health of the operators. Therefore, it is also very necessary to create an environment suitable for welding work according to the changes in the weather.

The above is a summary of some key points for everyone. You can take a look. JJY has been deeply engaged in the soldering industry12Over the years, we have always adhered to quality as the foundation and provided customers with a complete set of electronic soldering solutions. By adopting high-tech flux and tin material technologies, the solder is highly matched with the assembly and soldering scenarios, achieving soldering effects such as fast soldering speed, bright and full solder joints, good fluidity, and no collapse during formation, thereby enhancing the soldering efficiency for customers.