When facing the problem of poor solder paste productionWhen there is an erosion phenomenonIt is necessary to analyze its causesWhether the erosion method and protective measures are appropriate. JJYSolder paste manufacturerI suggest it to my friendsFrom the perspective of tin powder, how exactly can we solve some undesirable phenomena caused by solder paste, such as its astringency and other conditions?

The passivation treatment layer of copper powder particles is relatively thin, which is conducive to a better improvementSolder pasteIt has stability, and can also reduce the probability of solder beads. At the same time, the surface of the particles is smooth, with few defects, which reduces the reaction with solder paste and improves the viscosity stability of the solder paste.

Understanding the additional functions of copper powder. The overall spherical image of the external appearance is highly accurate, which is beneficial for packaging printing flipping, needle tube dot coating, and uniform tin application during this process. In addition, reducing the production of solder paste and the mutual friction and pushing of particles during application can achieve the effect of preventing the damage of the passivation treatment layer.

The powder has good fluidity and high density, which can better integrate into smaller holes and smaller needle tubes for tin discharge, and is more conducive to the future development prospects of lightweight products.

The particle size distribution is relatively narrow, and the uniformity of the solder paste is also relatively strong. The solder paste produced is good, which is conducive to the consistency of the solder paste amount during packaging and printing and the consistency of viscosity among batch numbers of solder paste. The powder form has good fluidity, which is convenient for solder paste packaging and printing, and is conducive to reducing the residual solder joints and generating round solder joints.

Select high-purity raw materials and, under the control of quality engineers, chooseCOMPOThe unique deep purification treatment smelting has reasonably reduced the oxidation level of aluminum alloy in the air, which can lower the non-conformity rate during the electric welding process and ensure the quality after welding at the same time.

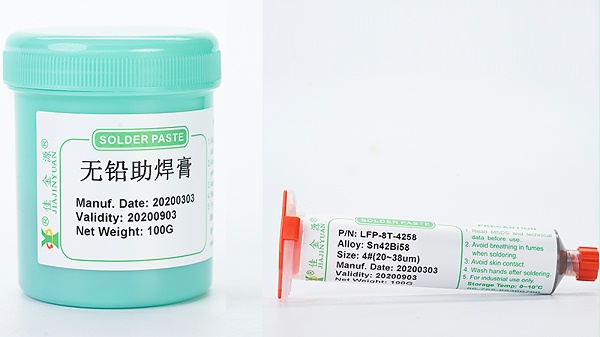

Shenzhen JJY brandThe solder paste has gone through many years12Annual research and development of solder paste, solder wire, solder wire, lead-free solder pasteLead-free flux pasteManufacturers of leaded solder paste, solder rods, leaded solder paste and other solder paste and wire products. Choose the solder paste manufacturer of JJY brand for solder paste.