Welding is a method of joining metals together. It uses heating methods to form a permanent and firm bond between the two metals at the contact surface through the mutual diffusion of atoms or molecules of the welding material. Different soldering objects require different working temperatures of the soldering iron. When judging the temperature of the soldering iron tip, you can touch the rosin with the electric soldering iron. If there is a "squeaking" sound when the soldering iron touches the rosin, it indicates that the temperature is appropriate. If there is no sound and only the rosin can be barely melted, it indicates that the temperature is low. If the tip of the soldering iron starts to smoke a lot as soon as it touches the rosin, it indicates that the temperature is too high. The solder paste manufacturer will explain this to you below:

Generally speaking, the main steps of welding are three:

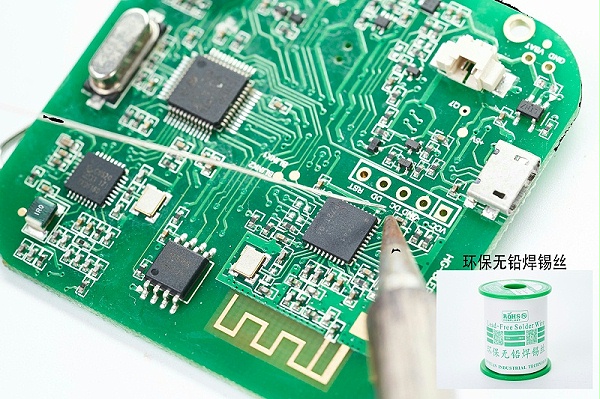

1First, melt a small amount of solder and rosin on the soldering iron tip, and then align the soldering iron tip and the solder wire simultaneously with the solder joint.

2When the flux on the soldering iron tip has not yet completely evaporated, touch the soldering iron tip and the solder wire to the solder joint simultaneously to start melting the solder.

3When the solder has soaked the entire solder joint, remove the soldering iron tip and solder wire simultaneously or remove the solder wire first. Wait until the solder joint is full and beautiful before leaving the soldering iron tip and solder wire.

The welding process is generally as follows2~3sIt is advisable. When soldering integrated circuits, the amount of solder and flux used must be strictly controlled. To prevent the integrated circuits from being damaged due to poor insulation of the soldering iron or the induced voltage on the casing by the internal heating element, in practical applications, the method of unplugging the power plug of the soldering iron and soldering while it is still hot is often adopted.

Solder wirePrecautions regarding temperature when soldering electronic components:

(1The welding temperature should be carried out at a relatively low level to ensure that the components are not damaged by thermal shock. If the melting point of the solder is180-220℃Between them, usually the welding temperature is higher than the actual melting temperature of the solder50℃The actual welding temperature is on the left and right220-250℃Within the range. According toIPC-SM-782It is stipulated that usually chip components are in260℃Only retained in the environment10sAnd some are heat-sensitivesmtThe heat resistance temperature of the components is lower. Besides,PCBThermal stress will also form after high temperatures, so the melting point of the solder should not be too high.

(2The molten solder must have good fluidity on the surface of the metal to be welded, which is conducive to the uniform distribution of the solder and lays the foundation for wetting.

(3The solidification time should be short, which is conducive to the formation of solder joints and convenient for operation.

(4After welding, the appearance of the weld points should be good for easy inspection.

(5It has good electrical conductivity and sufficient mechanical strength.

(6Good corrosion resistance. Electronic products should be able to operate in harsh environments such as high or low temperatures, smoke, etc., especially in military, aerospace, communication and large computers, etc. For this reason, solder must have excellent corrosion resistance.

(7The source of solder raw materials should be extensive, that is, the metal minerals that make up the solder should be abundant and the price should be low, so as to ensure a stable supply.