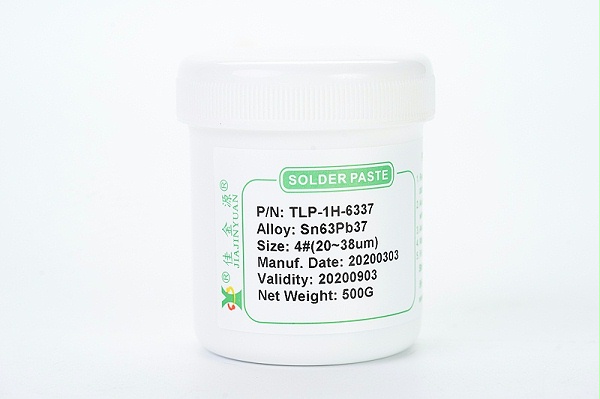

Low temperatureSolder pasteMelting point138Low-temperature solder paste is also known as low-temperature solder paste when the components on the surface mount cannot withstand it200°When the surface mount reflow process is required at or above temperatures, using low-temperature solder paste for soldering attacks serves to protect the components that cannot withstand high-temperature reflow solderingPCBVery much.LEDIt is well-received by the industry and its alloy composition is tin alloy. The temperature for low-temperature solder paste reflow soldering is170-200°Between.

There are many classifications of solder paste, such asLEDSolder pasteMiniSolder pasteMEMSSolder pasteIGBTSolder paste, high-temperature solder paste, low-temperature solder paste, etc. Only by knowing their differences can one choose the correct solder paste and apply it in the right place.earlysun8888It is believed that only by making the best use of everything and applying the right solder paste can one achieve twice the result with half the effort.

Characteristics of high-temperature solder paste

1.It has good printing rolling property and tinning property, and is suitable for low to0.3mmPrinting that can also be accomplished with pitch pads;

2.When printing continuously, its viscosity changes extremely little, and the operational life of the steel screen is long, exceeding8It will not dry out even after hours and still maintain a good printing effect.

3.The solder paste remains in its original shape for several hours after printing without collapse, and the surface mount components will not shift.

4.It has excellent welding performance and can exhibit appropriate wettability in different parts.

5.It can meet the requirements of welding equipment of different grades, does not need to complete the welding in a nitrogen-filled environment, and still shows good welding performance within a wide range of reflow oven temperatures.

6.High temperatureIGBTThere is very little residue left after solder paste soldering. It is colorless and has a high insulation resistance, and will not corrodePCBThe board can meet the requirement of no cleaning.

7.It has betterICTTest performance and there will be no misjudgment.

8.It can be used for coating through-hole rollers.Paste in hole"Process;"

9.Tin, silver, copperIGBTThe melting point of solder paste is relatively high, and it has high requirements for the furnace. However, tin-silver-copper solder paste has a good soldering effect, high mechanical strength, less rosin residue, and is white and transparent. When printing high-temperature solder paste, it has good moisture retention, can achieve stable printability and demolding, and can be continuously printed on steel screens8When it is small, it has good solderability, good solder climbing, and full and bright solder joints.

Lead-freeLow-temperature solder pasteAs the name suggests, in the lead-free solder paste series, the melting point is138℃The solder paste is called low-temperature solder paste when the components used for surface mount technology cannot withstand it138℃When the temperature is above and the surface mount reflow process is required, the soldering process should be carried out using low-temperature solder paste. To protect components that cannot withstand high-temperature reflow soldering andPCBThe board is very uncomfortableLEDIndustry welcome. Its alloy composition isSnBi(sn42bi58),The particle size of tin powder is between25~45umBetween.

For those who want to know about solder paste, solder paste, low-temperature solder paste, solder wire and solder bar, welcome to consult Shenzhen JJY Industrial Technology Co., LTD. Let's learn and grow together!