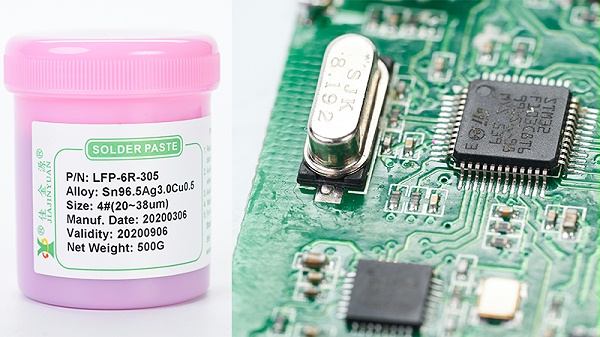

inPCBASolder pasteDuring the welding process, due to the influence of factors such as welding materials, techniques, and personnel, it may lead toPCBAThe phenomenon of poor soldering is introduced by Shenzhen JJY Solder Paste Manufacturer as a common onePCBAPoor welding phenomenon:

1,PCBAThere is too much residue on the board surface

PCBAExcessive residue on the board may be due to insufficient preheating or too low preheating temperature before soldering, or insufficient temperature of the tin furnace;The boarding speed is too fast;Anti-oxidant and anti-oxidation oil were added to the tin liquid;Too much flux has been applied;The component feet and the orifice plate are not proportional(The hole is too big.)Cause the flux to accumulate;It is caused by factors such as not adding thinner for a relatively long time during use.

2Corrosion occurs, the components turn green, and the solder pads turn black

The main reason is that insufficient preheating leads to a large amount of flux residue and too many harmful substances remaining;The flux that needed to be cleaned was used, but it was not cleaned after the welding was completed.

3False welding

False soldering is a very common defect and poses a significant threat to the board. It is mainly related to the insufficient or uneven amount of the coating agent.

Some solder pads or solder feet are severely oxidized;pcb Improper wiring;The foaming pipe is clogged, resulting in uneven foaming and uneven application of flux;The operation method was improper when tinning by hand;The inclination Angle of the chain is unreasonable;It is related to the cause of peak inequality.

4Cold welding:

The surface of the weld point is in the form of bean curd residue. It is mainly caused by insufficient welding temperature or too short welding time. In addition, if the flux activity in the solder paste is insufficient, it may also lead to cold soldering.

The specific characteristics of cold welding include a gray and dull surface of the welding point, and when observed under a microscope, the welding point appears granular. This adverse phenomenon may be caused by improper setting of the reflow furnace temperature curve, too fast passing speed, overly dense placement of products during passing, and deterioration of solder paste, etc.

5The solder joint turns white:

Uneven and dull. It is generally caused by excessively high welding temperature or overly long heating time. The strength of this defective solder joint is insufficient, and it is very likely to cause a short circuit fault of components when subjected to external force.

6Pad stripping:

The main reason is that the solder pads are exposed to high temperatures, causing them to peel off from the printed circuit board. This poor solder joint is highly likely to cause short circuits in components.

7Tin beads

In terms of technology:Low preheating temperature(The flux solvent has not completely evaporated);The loading speed is too fast and the preheating effect is not achieved:The chain is not tilted well, and the tin liquid is notpcbThere are bubbles in between. When the bubbles burst, tin beads are produced;Improper operation during tin immersion by hand;The working environment is damp.;

pcbThe problem:The board surface is damp and there is moisture produced;pcbThe design of the air leakage hole is unreasonable, resulting inpcbThere is air between it and the molten tin;pcbThe design is unreasonable. The feet of the parts are too dense, causing air pockets.

PCBAThe causes of poor solder paste soldering are numerous. Among them, strict control over each process is necessary to reduce the impact of previous processes on subsequent ones.

As a solder paste manufacturer with sixteen years of experience, JJY has been committed to the research, development, production and sales of solder paste. Our product quality is stable, with no solder connection, no false soldering, and no monument erection. Residual Wuxi beads, bright and full solder joints, firm welding, and excellent electrical conductivity. If you have any needs, please feel free to contact us.