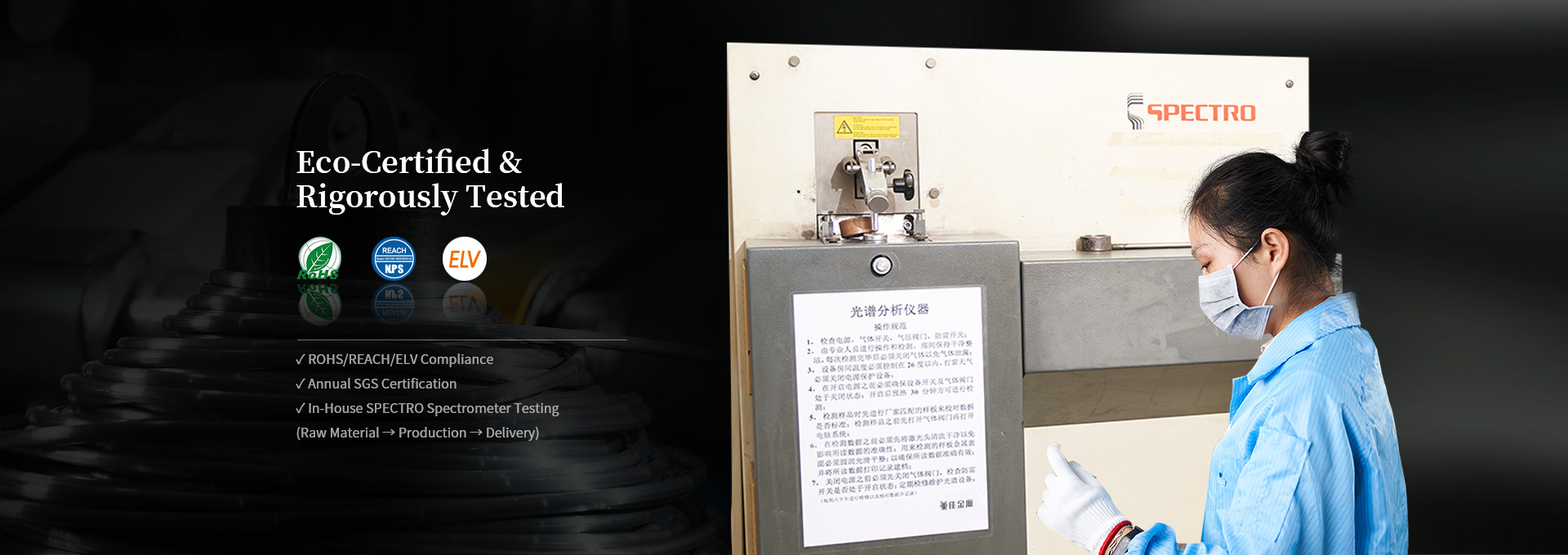

JJY ensures rigorous process control and continuous refinement at every stage.

-

-

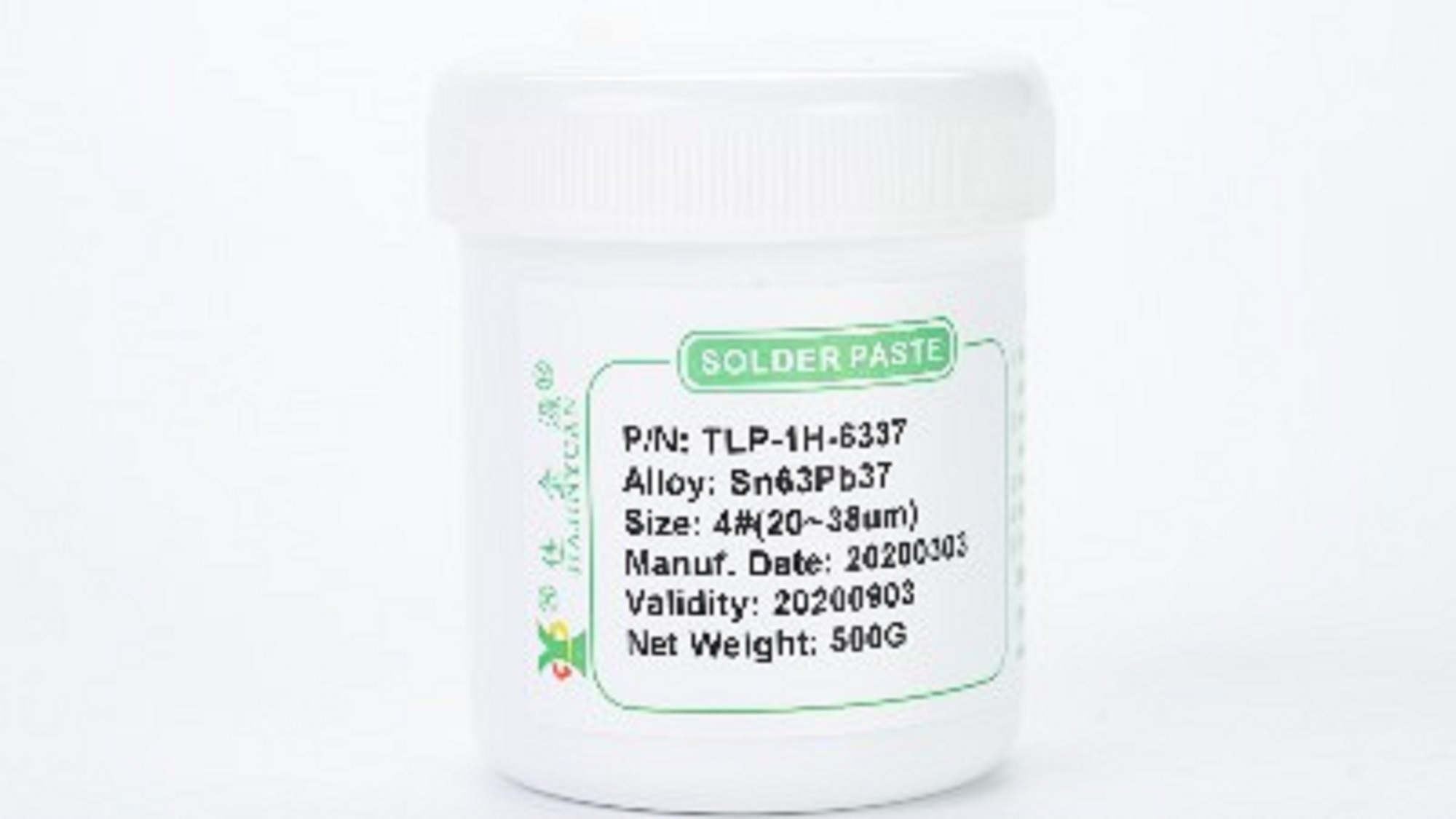

Solder Paste

-

The weld points are firm, bright and full

The weld points are firm, bright and fullWith 17 years of R&D and production experience, we have scientifically mastered modern process formulas, ensuring that the solder paste is highly compatible with the soldered products. The solder joints are firm, bright, uniform, full and free of solder beads.

-

Low residue, no need for cleaning

Low residue, no need for cleaningWe have developed and formulated a no-wash and environmentally friendly flux paste, which leaves little residue after welding, has high insulation resistance, a clean board surface without corrosion, and forms a protective layer to prevent the re-oxidation of the base material.

-

It has strong wettability and good tin crawling

It has strong wettability and good tin crawlingHigh-performance thixotropic agents are added to the solder, making the solder paste highly active. The molten solder paste significantly wets the solder pad, reducing the phenomenon of false soldering during the soldering process.

-

The printing is stable and has good demolding properties

The printing is stable and has good demolding propertiesThe tin powder particles have good roundness and uniform size. During printing, there are no trailing, sticking or splashing phenomena. There is no collapse, sharp or continuous tin connection during molding. The viscosity change is small during continuous printing, and it does not dry out. The components do not shift.

-

-

-

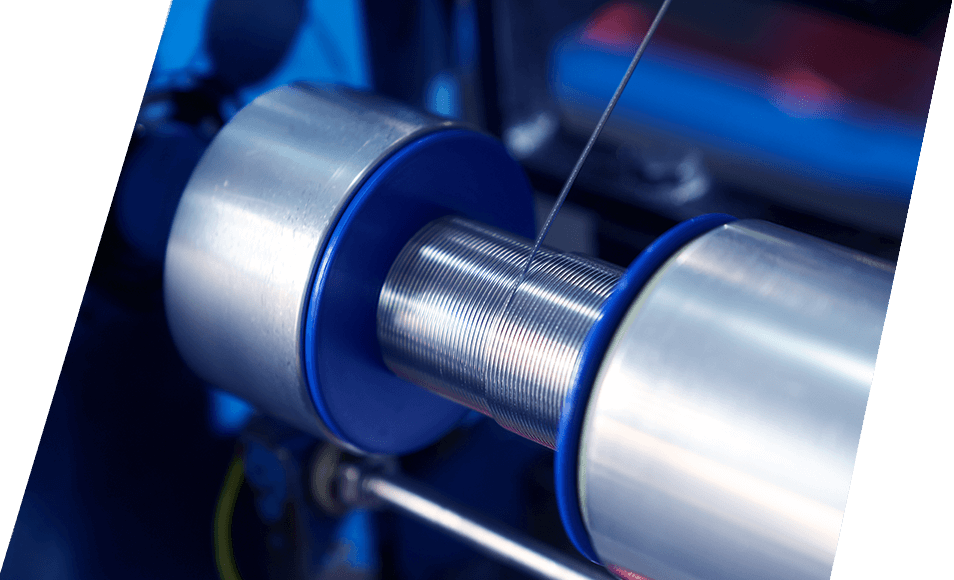

Solder Wire

-

Stable performance and safe to use

Stable performance and safe to usePrecise process control ensures that the rosin flux is evenly and continuously distributed, with no interruption of rosin. The soldering speed is fast, without sharpening or splashing. Customized tin wires with high compatibility can be made according to requirements.

-

The weld points are bright and the workmanship is excellent

The weld points are bright and the workmanship is excellentStrictly adhering to national standards, it is made of high-purity virgin refined tin, electrolytic copper and pure silver materials, with few elemental impurities, sufficient degree, bright surface of the tin wire, uniform winding without tangling, little smoke and no unpleasant smell during welding, bright and firm weld points, and strong reliability.

-

It has good wettability and is easy to tin

It has good wettability and is easy to tinThe self-developed flux can remove the oxide layer and surface oil stains of the soldered material, reduce the surface tension of the soldered material, increase the welding area, has good wettability, is easy to tin, and has no bridging.

-

Luoyang Iron has less scum and requires no cleaning

Luoyang Iron has less scum and requires no cleaningAdopting a scientific rosin flux formula, it is strictly produced in accordance with national and EU standards, ensuring excellent solderability while guaranteeing low corrosiveness of the flux, fast welding speed and minimal residue after welding.

-

-

-

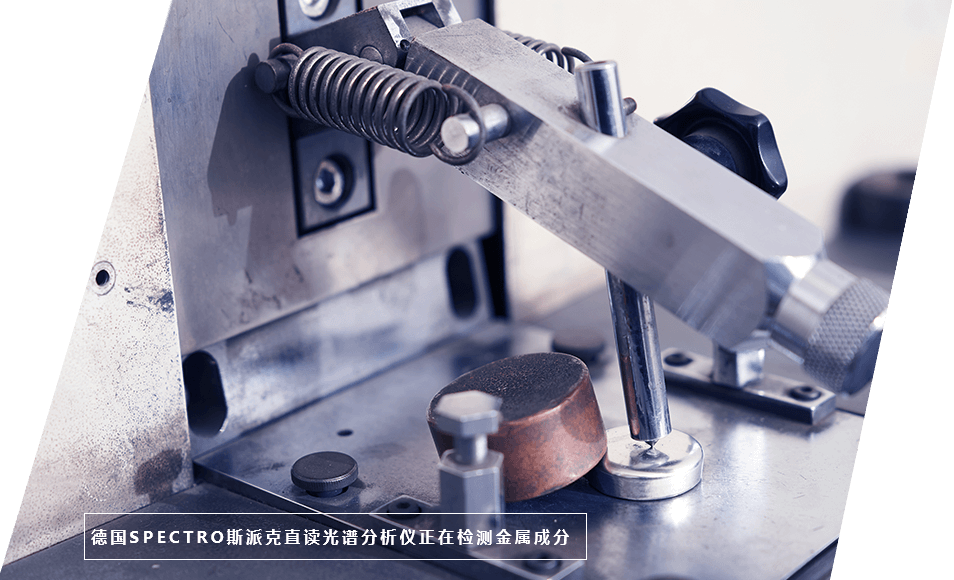

Solder Bar

-

The speed of going to tin is very fast

The speed of going to tin is very fastStrictly adhering to national standards, it is made of high-purity primary refined tin, electrolytic copper and pure silver materials. After melting, it has low viscosity, good wettability, high fluidity, excellent solderability and is easy to solder, effectively improving the welding efficiency.

-

Strong antioxidant capacity

Strong antioxidant capacityThe proprietary anti-oxidation alloy technology endows the tin bars with unique anti-oxidation properties, ensuring a very low oxidation slag production rate during the welding process and reducing unnecessary waste.

-

The weld points are bright and firm

The weld points are bright and firmAfter special process adjustment and refining treatment, the metallographic particles are very fine, the weld points are firm, bright and full, without false welding, voids, sharp points or bridging phenomena, and there are no residual impurities after welding.

-

The slag discharge is very low-tech

The slag discharge is very low-techHigh-antioxidant formulas are combined with free technical services provided by engineers, such as reasonable setting of temperature, wave height, chain speed, time of slag removal and tin adding, inspection and correction of components, flux compatibility, etc. Control the slag discharge rate at7~20%. High price for tin slag recycling or exchange for new tin bars.

-

Lead-free

Lead-free There is lead

There is lead 305T4

305T4 305T4

305T4 JJY's soldering solutions for the electronics industry

JJY's soldering solutions for the electronics industry

JJY LED Industry Soldering Solutions

JJY LED Industry Soldering Solutions JJY's soldering solutions for the photovoltaic cell industry

JJY's soldering solutions for the photovoltaic cell industry JJY's soldering solutions for the power battery industry

JJY's soldering solutions for the power battery industry JJY Intelligent Automotive Industry Soldering Solutions

JJY Intelligent Automotive Industry Soldering Solutions JJY's 5G communication industry soldering solution

JJY's 5G communication industry soldering solution

R&D Team

R&D Team Quality

Quality Experience

Experience Technical

Technical

![[Case Analysis] Will using lead-free solder paste from morning till afternoon affect product quality? [Case Analysis] Will using lead-free solder paste from morning till afternoon affect product quality?](http://www.jjytinsolder.com/resource/images/0b934edd6c4a49f3b3501ba5743f6c3e_3.jpg)

Enterprise Video

Enterprise Video Honors

Honors Factory Display

Factory Display

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name  WeChat

WeChat WeChat official account

WeChat official account